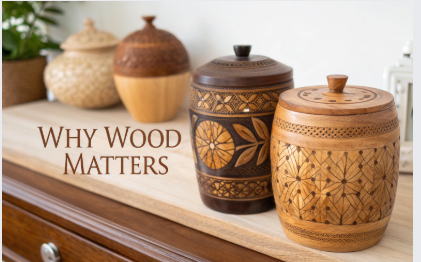

In a world of automation and mass production, what’s the value of a wooden jar carved by hand?

Wooden jar artisan workshops preserve centuries-old craftsmanship through sustainable methods, producing functional art that blends natural materials with cultural heritage.

This blog explores how traditional wooden jar making survives and thrives in the modern era—and how businesses like PauPack support these artisans with global B2B supply chain partnerships.

Why Do Wooden Jar Workshops Still Matter?

Most packaging is plastic or glass—so why insist on wood?

Wooden jar workshops matter because they preserve cultural identity, empower rural economies, and offer brands natural, luxurious packaging alternatives that machines can’t replicate.

Let’s dive into why this craft has more relevance than ever.

Cultural Preservation

Every region has its own wood-carving lineage—from Japanese kiri boxes to Balinese teak jars and Nordic birch bark containers. These aren’t just jars—they’re symbols of local design philosophy, ritual, and history.

Economic Empowerment

In rural parts of Indonesia, India, Morocco, and Eastern Europe, wood carving remains one of the few viable trades. Artisan workshops often support entire villages. When global buyers choose handmade wooden jars, they directly impact livelihoods.

Environmental Harmony

Artisan wooden jars use renewable resources like bamboo, acacia, or reclaimed wood. Many workshops follow traditional low-waste, chemical-free finishing methods—far more eco-friendly than industrial alternatives.

At PauPack, we’ve seen how clients light up when they unbox our hand-turned wooden powder jars. There’s something special about holding packaging that feels alive.

How Are Wooden Jars Made in Traditional Workshops?

Unlike plastic injection molding, crafting wooden jars is a slow, tactile process.

Artisan workshops rely on traditional hand tools, natural finishes, and seasonal rhythms to shape, dry, and finish each wooden jar.

Let’s walk through the stages:

1. Material Selection

The workshop begins by choosing the right wood—often locally sourced. Key traits include grain texture, oil content, and aroma. Each type affects the jar’s aesthetic and function.

| Wood Type | Origin | Traits | Common Use |

|---|---|---|---|

| Teak | Southeast Asia | Durable, moisture-resistant | Cream jars |

| Maple | North America | Pale, smooth grain | Essential oil cases |

| Olive wood | Mediterranean | Aromatic, fine-grained | Lip balm jars |

| Bamboo | China/India | Fast-growing, lightweight | Refill jars |

| Walnut | Europe/US | Rich color, premium feel | Gift boxes |

2. Hand Turning and Carving

Skilled artisans use foot-powered lathes or electric carvers to shape the jar. Each turn of the tool follows the wood’s natural rhythm. Unlike factory molds, no two jars are identical.

3. Drying and Stabilization

Wood is left to air dry for days—or even weeks—to prevent future cracking. Some workshops use smoke-curing or sun drying to stabilize the wood.

4. Surface Finishing

Instead of chemical coatings, many use beeswax, tung oil, or shellac for a natural sheen and food-safe finish. Some apply herbal infusions or rice polish for fragrance.

5. Assembly and Fitting

Lids are carved to match the jar’s curvature. Many workshops use friction-fit or cork liners instead of plastic threads, preserving the handmade feel.

At PauPack, we collaborate with 12+ artisan workshops worldwide to produce wooden packaging that meets modern hygiene standards without sacrificing craft.

What Challenges Do Artisan Workshops Face Today?

Craftsmanship is noble—but not easy.

Artisan wooden jar makers struggle with raw material shortages, limited market access, and a lack of digital infrastructure to scale.

Raw Material Regulations

Many hardwood species are now protected or require certification. Sustainable sourcing raises costs and limits availability. PauPack works only with FSC-certified suppliers and supports planting projects in Indonesia and Vietnam.

Market Visibility

Most workshops don’t have websites, catalogs, or sales staff. They rely on middlemen or small-scale exhibitions. That limits global exposure and pricing power.

Production Bottlenecks

Because work is done by hand, scaling orders (e.g. 5,000 pieces/month) is tough without losing quality. PauPack provides production planning tools and training to help workshops gradually grow capacity.

| Challenge | Solution by PauPack |

|---|---|

| Limited digital tools | Supplier onboarding kits & photography |

| Inconsistent quality | Custom molds & sample approvals |

| Long lead times | Forecast-based rolling orders |

| Language barriers | Local liaison teams & bilingual documentation |

With the right partnership, artisan workshops can thrive without losing their soul.

Why Are Wooden Jars a Smart Choice for Premium Brands?

Artisan packaging is not just nostalgic—it’s strategic.

Wooden jars signal luxury, sustainability, and authenticity. They help premium brands stand out while aligning with modern values.

Luxury & Differentiation

In a sea of plastic and glass, a hand-carved walnut balm jar turns heads. It enhances unboxing, drives social shares, and strengthens shelf presence.

Sustainability Messaging

Consumers are increasingly skeptical of “eco” claims. A wooden jar backed by artisan stories and FSC certification tells a credible, tactile sustainability narrative.

Reusability

Unlike plastic jars, wooden containers are often repurposed. Customers use them for jewelry, spices, or travel tins—extending brand visibility long after first use.

Customization Potential

Wood accepts engraving, burning, inlay, and carving—ideal for private label branding. PauPack offers:

-

Logo laser engraving

-

Custom lid shapes (heart, hexagon, leaf)

-

Mixed media lids (wood + brass, resin, shell)

-

Hand-burned limited-edition series

How Does PauPack Work with Artisan Workshops?

We don’t just buy wooden jars—we co-create them.

PauPack builds long-term partnerships with artisan workshops across Asia and Europe, supporting design, quality, and export-readiness.

Local Sourcing and Audits

Each workshop is visited and vetted. We assess tools, worker conditions, and drying methods. Only partners aligned with our sustainability and quality goals are approved.

Co-design and R&D

We supply design sketches, technical drawings, and trend boards. Workshops contribute their regional techniques—like Japanese joinery or Moroccan resin inlay.

Training and Infrastructure

We fund tools, drying rooms, and solar-powered lighting to improve output and safety. This turns “craft” into a reliable supply partner without removing artistry.

Logistics and Certification

PauPack handles all export paperwork, batch labeling, FSC tracking, and QC inspections—bridging the gap between slow craft and fast markets.

How Can Brands Use Wooden Jars Creatively?

Wooden jars aren’t just for creams. Brands are reimagining them across formats.

From candle jars to powder containers, wood adds charm, warmth, and surprise across many beauty and wellness SKUs.

Use Cases:

-

Solid perfume jars

-

Refillable lip balm tins

-

Scented body butter containers

-

Matcha face mask jars

-

CBD balm packaging

-

High-end aromatherapy capsules

-

Home spa gift kits

Design Inspirations

| Style | Description | Ideal For |

|---|---|---|

| Rustic Scandinavian | Pale woods, raw edge | Organic skincare |

| Luxe Oriental | Teak + brass inlay | Herbal balms |

| Zen Minimalist | Sanded bamboo + white seal | Mindful brands |

| Folk Art Carved | Floral motifs, dark stain | Seasonal gift lines |

PauPack maintains a gallery of 100+ wooden jar designs ready for private label or custom adaptations.

Conclusion

Wooden jar workshops are more than vendors—they’re culture keepers. Their survival depends on thoughtful collaboration, long-term vision, and B2B buyers who value soul over speed.

At PauPack, we’re honored to support these artisans. Together, we craft wooden packaging that doesn't just contain a product—but tells a story worth preserving.

Ready to package your product in a jar that breathes tradition and beauty? Let’s connect and co-create something timeless.