Precision & Compliance: The Top 5 Medicine Syrup Bottle Manufacturers for Pharmaceutical Brands

In the pharmaceutical and nutraceutical sectors, packaging is more than a container—it is a promise of purity, stability, and precise dosage. For liquid medications like cough syrups, oral suspensions, and health supplements, the bottle must be chemically inert, stable enough for long-term storage, and, most crucially, compatible with precise dispensing systems. Choosing the right medicine syrup bottle manufacturer is a critical decision that directly impacts patient safety and regulatory compliance.

Medicine syrup bottles typically require high-quality glass or inert plastic (like PET or HDPE), tight seals to prevent contamination, and often specialized neck finishes to accommodate measuring cups or dosing spoons/syringes. Compliance with stringent regulatory bodies (like the FDA, EMA, and national pharmacopeias) is non-negotiable. The leading factories in this niche are experts in clean-room production, rigorous quality control, and providing comprehensive documentation for pharmaceutical clients. They serve as essential suppliers for large-scale wholesale production and specialized OEM packaging for unique liquid formulations.

This guide profiles five of the top medicine syrup bottle manufacturers and suppliers. We will delve into their expertise in pharma-grade production, their capacity for bulk orders, and their commitment to the quality and safety standards demanded by the healthcare industry.

📝 How to Select a Pharma-Grade Syrup Bottle Supplier

Sourcing pharmaceutical packaging is a high-stakes process where regulatory compliance overrides all other considerations. Before placing a bulk or OEM order, evaluate potential manufacturers based on these core criteria:

✅Pharmaceutical Grade Certification: The factory must adhere to Good Manufacturing Practice (GMP) standards. Look for certifications like ISO 15378 (primary packaging materials for medicinal products) or related pharma-specific ISOs. Ensure the bottles are manufactured in controlled environments (e.g., cleanrooms) to prevent contamination.

✅Material Inertness & Compatibility: The bottle material (typically Type I, II, or III glass, or specialized plastics) must be chemically inert and proven compatible with your liquid formulation, particularly regarding leaching or absorption. Request comprehensive test data on material composition.

✅Dispensing Accuracy: The bottle’s neck finish must be precise to ensure a tight seal with a cap and accurate fit with dosing devices (measuring cups, oral syringes). Discuss with the supplier their tolerances for neck finish dimensions and thread consistency.

✅Closure System Integrity: For syrups, the closure must maintain a perfect barrier against oxygen and moisture. Suppliers should offer tamper-evident closures (TE) and, if required, certified child-resistant closures (CRC).

✅Documentation & Traceability: Pharmaceutical supply chains require complete traceability. The manufacturer must provide detailed batch records, certificates of analysis (CoA), and evidence of compliance with international pharmacopeias (USP, EP, JP).

With these compliance points in mind, let’s explore the top manufacturers that excel in delivering safety and precision.

🇨🇳1. Paupack (paupacking.com)

Website: https://www.paupacking.com

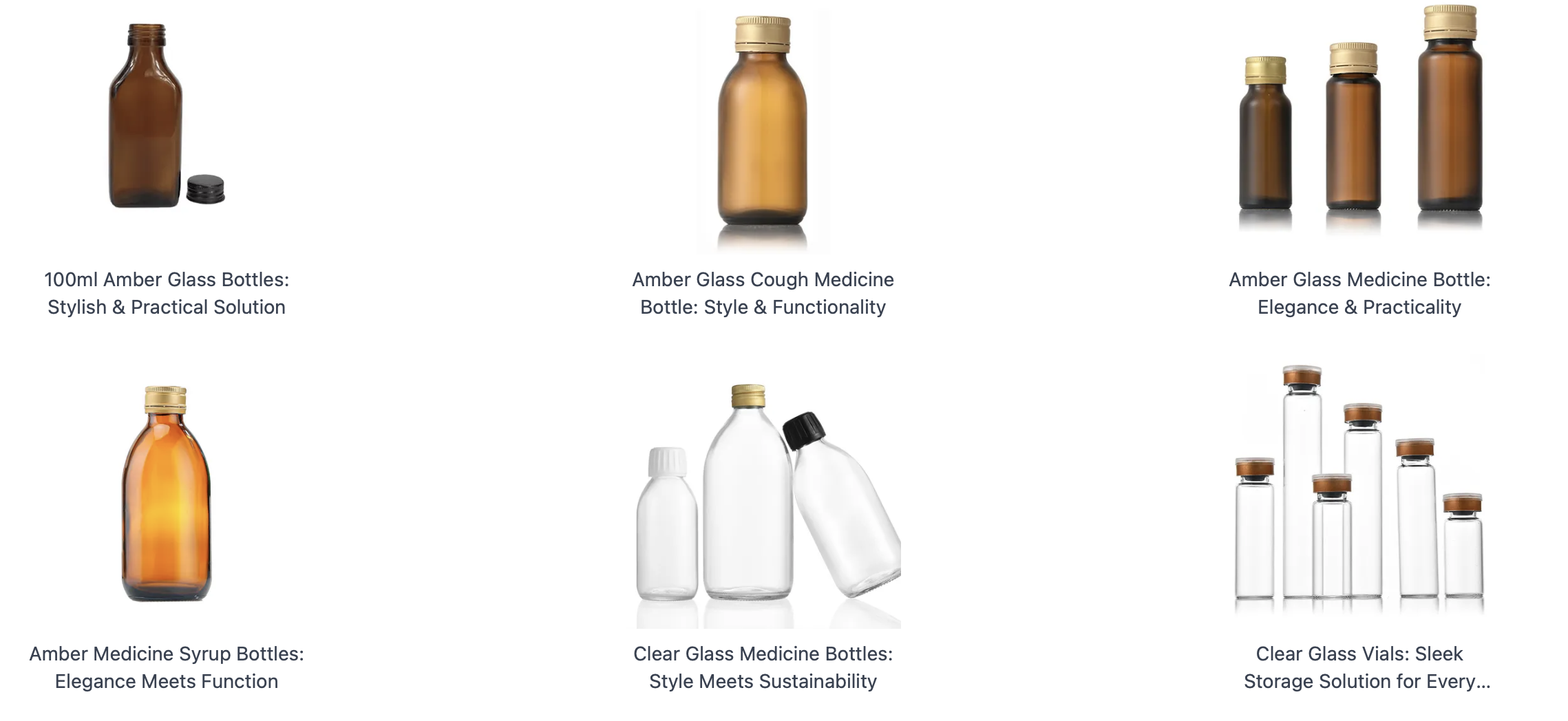

Paupack has strategically positioned itself as a high-quality, comprehensive supplier for the demanding pharmaceutical and nutraceutical sectors. They offer a range of high-quality glass and plastic syrup bottles, focusing on materials known for their inertness and stability, making them suitable for bulk orders of pharmaceutical liquids.

What sets Paupack apart for medical and supplement brands is their capacity to provide a complete, validated system. They not only supply the bottles but also the crucial closures and dosing accessories, such as tamper-evident screw caps, calibrated measuring cups, or oral adapters for syringes. This one-stop approach minimizes the risk of component mismatch and simplifies the supply chain for wholesale and private label clients. Furthermore, Paupack's strong customization capabilities allow for unique bottle shapes or integrated dosing features (OEM), all while maintaining strict quality control suitable for medical applications.

Key Strengths:

-

Integrated Medical Solution: Supplies bottles, verified closures (TE/CRC), and dosing accessories as a cohesive unit.

-

Focus on Precision: High consistency in neck finish manufacturing for accurate dispensing.

-

Supplier Versatility: Offers both pharmaceutical-grade glass and inert plastic options.

-

Strong OEM Potential: Ability to customize bottle shapes and dispensing features for private label products.

🇨🇳2. Shandong Pharmaceutical Glass Co., Ltd. (SPG)

Website: http://www.spgpack.com

As a leading, publicly-listed glass manufacturer in China with a name that defines its specialization, SPG is a colossal player in the pharmaceutical packaging market. They are a powerhouse for glass ampoules, vials, and, critically, high-quality medicine syrup bottles. Their foundation in pharmaceutical production means their entire manufacturing environment is geared toward rigorous quality control and compliance.

SPG's scale allows them to handle massive bulk orders for global pharmaceutical companies, offering various types of glass (from Type I borosilicate to Type III soda-lime glass) to meet different formulation requirements. For brands seeking reliability, consistency, and a proven track record with major global pharma corporations, SPG is an essential OEM partner. Their commitment to clean production and international pharmacopeia standards makes them a benchmark in the industry.

Key Strengths:

-

Massive Production Scale: Ideal for global, high-volume wholesale orders.

-

Strict Pharma Compliance: Adheres to the highest international pharmaceutical standards and GMP.

-

Versatility in Glass Type: Produces bottles from different types of glass to suit various chemical needs.

🇩🇪3. Gerresheimer AG

Website: https://www.gerresheimer.com/

Gerresheimer is a global leader in primary packaging solutions for pharmaceuticals, with headquarters in Germany and manufacturing plants worldwide. They are highly renowned for their expertise in glass and plastic packaging for injectable drugs, and their oral dosage division, which includes medicine syrup bottles, is equally respected.

Gerresheimer focuses on high-value, engineered solutions. They offer advanced plastic barrier bottles and highly specialized glass containers designed for superior chemical resistance and stability. They are the go-to supplier for large multinational pharmaceutical companies that require global supply consistency, cutting-edge technology, and unparalleled regulatory expertise. While their prices reflect their premium position, their quality is second to none for critical applications.

Key Strengths:

-

Global Leader: Worldwide manufacturing and supply capabilities.

-

Cutting-Edge Technology: Focus on advanced, engineered packaging solutions (glass and plastic).

-

Uncompromising Quality: Known for the highest standards of reliability and regulatory compliance.

🇺🇸4. Berry Global

Website: https://www.berryglobal.com

Berry Global is one of the largest plastic packaging manufacturers in the world. Their massive Healthcare division is a major supplier of plastic pharmaceutical containers, including syrup bottles, vials, and specialized closures. Their strength lies in their ability to produce enormous quantities of highly consistent, compliant plastic packaging.

For liquid supplements, over-the-counter (OTC) medicines, and formulations better suited for plastic, Berry Global offers a massive portfolio of certified products. They are experts in child-resistant closures and tamper-evident solutions that are vital for OTC syrup bottles. Their global footprint and high capacity make them an ideal partner for global wholesale supply chains.

Key Strengths:

-

Global Plastic Powerhouse: Massive capacity for high-volume plastic bottle production.

-

Expertise in Closures: Strong focus on certified CRC and TE closures for safety.

-

Diverse Material Range: Offers various plastics (PET, HDPE, PP) for different formulation needs.

🇺🇸5. West Pharmaceutical Services

Website: https://www.westpharma.com/

While West is primarily famous for its components for injectable drugs (stoppers, plungers, etc.), their deep involvement in drug delivery and container closure systems makes them an essential reference point for pharmaceutical packaging solutions. They specialize in high-quality sealing solutions that ensure container closure integrity (CCI)—a crucial factor for liquid medicines.

Including West highlights the importance of the closure system itself. While they may not manufacture the glass bottle, they often partner with bottle manufacturers to provide the critical rubber or polymer seals and dosing mechanisms that transform a basic bottle into a pharmaceutical container. They are a key OEM supplier for advanced dispensing technologies within the broader medical packaging landscape.

Key Strengths:

-

Focus on Integrity: Specialist in container closure integrity (CCI).

-

High-Quality Components: Provides critical rubber/polymer seals and dosing components.

-

Deep Regulatory Knowledge: Essential partner for validation and compliance testing of the final package assembly.

🏆Conclusion

The packaging for liquid medications must guarantee safety, stability, and dosing accuracy. It is a sector where quality control, compliance documentation, and engineering precision are absolutely paramount. The manufacturers listed above are leaders in this highly regulated field, ensuring the integrity of healthcare products worldwide.

For growing pharmaceutical and nutraceutical brands seeking a strategic partner that can simplify complexity, Pau-Shing Packaging offers a decisive advantage. Their ability to deliver a unified, high-quality system—bottle, closure, and dosing accessory—streamlines the supply chain while maintaining the rigorous quality standards essential for medical wholesale and private label production.

👉 Contact Us Now to explore your perfect bottle match.