Trying to choose the right blow molding method for PCR bottles but overwhelmed by options?

This guide compares the top 5 blow molding technologies for PCR bottles, helping you choose the most cost-effective and efficient method for sustainable packaging.

From sustainability goals to supply chain feasibility, the method you pick affects everything from material yield to product performance. Let's explore which technology best supports your PCR (Post-Consumer Resin) packaging needs.

What Is PCR Blow Molding and Why Does It Matter for Sustainable Packaging?

Switching to PCR bottles is great—but only if your manufacturing method supports it.

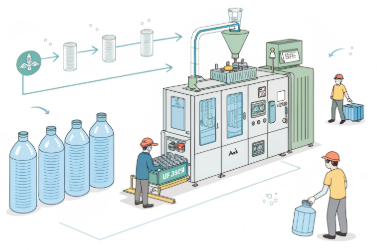

PCR blow molding is the process of forming new bottles from recycled plastic using one of several shaping technologies. It supports circular economy goals and reduces raw material use.

Why Brands Are Choosing PCR Bottles

Post-consumer resin (PCR) is plastic that’s been used, collected, cleaned, and reprocessed. Using it means:

-

Lower environmental footprint

-

Less virgin plastic demand

-

Support for recycling infrastructure

But PCR behaves differently from virgin resin. It can be more brittle, more variable in color and clarity, and more sensitive to heat. That’s why the molding method matters.

At PauPack, we’ve developed dedicated blow molding solutions optimized for PCR clarity, strength, and repeatability—especially important for beauty and health brands targeting eco-conscious consumers.

How Does Extrusion Blow Molding Perform with PCR Materials?

Looking for simple, low-cost PCR bottle production for bulk products?

Extrusion Blow Molding (EBM) is cost-effective and versatile, ideal for opaque or thick-walled PCR bottles—but it may lack the clarity needed for high-end cosmetics.

Overview of EBM with PCR

In EBM, a hot tube of plastic (parison) is extruded, then air-blown into a mold. It works best with HDPE, LDPE, and sometimes PP. With PCR:

-

Wall thickness can be uneven

-

Color variation is more visible

-

It suits large volume, low-margin products

Ideal for:

-

Shampoo bottles

-

Household cleaners

-

Industrial packaging

| Metric | Rating |

|---|---|

| Cost Efficiency | ★★★★★ |

| Clarity | ★☆☆☆☆ |

| Mold Flexibility | ★★★★☆ |

| PCR Compatibility | ★★★☆☆ |

At PauPack, we often recommend EBM for PCR-based lotion bottles in natural or tinted hues where clarity isn’t a priority but volume and speed are.

Is Injection Stretch Blow Molding (ISBM) the Best for Clarity and Precision?

When your brand needs crystal-clear PCR bottles, ISBM is your go-to.

ISBM creates premium-looking PCR containers with tight tolerances and excellent clarity—perfect for beauty or supplement brands.

How ISBM Works

-

Preforms are injection-molded first

-

Then reheated and stretch-blown into shape

Because this method controls material orientation during stretching, it improves:

-

Strength

-

Clarity

-

Barrier properties

Ideal for:

-

Essential oil bottles

-

Face serums

-

Supplements in clear PET

| Metric | Rating |

|---|---|

| Cost Efficiency | ★★★☆☆ |

| Clarity | ★★★★★ |

| Mold Flexibility | ★★★★☆ |

| PCR Compatibility | ★★★★☆ |

Our ISBM PCR lines at PauPack are specially tuned to handle 30–100% PCR PET blends without yellowing or hazing, offering brands upscale packaging without virgin plastic guilt.

What Are the Advantages of Two-stage Reheat Stretch Blow Molding?

Need flexibility across bottle shapes and sizes, with reliable PCR performance?

Two-stage Reheat Stretch Blow Molding separates preform making and blowing, offering high volume and shape consistency—great for diversified PCR packaging lines.

Why It’s Popular for PCR

-

Enables preform standardization

-

Allows inventory buffer

-

Suitable for high-speed, automated lines

This method is especially useful when sourcing preforms externally or running multiple product SKUs from the same base material.

Ideal for:

-

Beverage bottles

-

PCR jars with wide mouths

-

Body sprays or mists

| Metric | Rating |

|---|---|

| Cost Efficiency | ★★★★☆ |

| Clarity | ★★★★☆ |

| Mold Flexibility | ★★★★☆ |

| PCR Compatibility | ★★★★☆ |

We recommend this approach for brands launching PCR-based diffusers and room sprays where consistent shape and clarity enhance shelf appeal.

How Do Costs and Efficiencies Compare Across Technologies?

You’ve got options—but which one gives you the best ROI with PCR?

For PCR bottles, ISBM leads in clarity, EBM wins on cost, and two-stage reheat molding balances flexibility with scale.

Comparative Summary

| Technology | Cost | Clarity | Speed | Ideal Use Case |

|---|---|---|---|---|

| Extrusion Blow Molding (EBM) | Low | Low | Fast | Opaque bulk bottles |

| Injection Stretch Blow (ISBM) | Medium | High | Medium | Clear premium bottles |

| Two-stage Reheat Stretch | Medium | High | High | Standardized high-volume bottles |

| Injection Blow Molding (IBM) | High | Medium | Slow | Small PCR jars, pharma packaging |

| Compression Blow Molding | Medium | Medium | Medium | Tubes and closures |

At PauPack, we assess your bottle function, volume, and sustainability goals before recommending a molding method. That’s how we ensure packaging that performs and aligns with your brand mission.