Sustainability is no longer optional—especially in the beauty and wellness packaging world.

PLA bottles generate up to 80% fewer carbon emissions than traditional plastics like PET or HDPE, making them a powerful tool for eco-conscious brands.

But are they right for your product line? Let’s dive into the data and practical considerations.

What Is PLA and How Does It Differ from Traditional Plastics?

PLA, or polylactic acid, is a bioplastic made from renewable plant sources like corn starch or sugarcane.

Unlike petroleum-based plastics, PLA is biodegradable, compostable under industrial conditions, and emits significantly less CO₂ during its lifecycle.

Here’s a breakdown:

| Property | PLA | PET (Traditional Plastic) |

|---|---|---|

| Source | Corn, sugarcane | Petroleum |

| Biodegradability | Yes (industrial composting) | No |

| Carbon Emissions | Low | High |

| Recyclability | Limited infrastructure | Widely recyclable |

| Heat Resistance | Lower | Higher |

| Appearance | Clear, glossy | Clear or colored |

At PauPack, we offer PLA bottles in various shapes and volumes, perfect for low-viscosity skincare, aromatherapy blends, and non-oily formulas.

How Much Carbon Can You Save by Switching to PLA Bottles?

This is the question every brand with a sustainability mission should ask.

Switching from PET to PLA bottles can reduce carbon emissions by up to 80% per unit, depending on the bottle weight and end-of-life treatment.

Life Cycle Emissions Comparison (per 1000 bottles)

| Material | Emissions (kg CO₂) | Emission Source |

|---|---|---|

| PET | ~320 kg CO₂ | Oil extraction, polymerization, transport |

| HDPE | ~280 kg CO₂ | Fossil-fuel intensive |

| PLA | ~60–80 kg CO₂ | Crop cultivation, fermentation, molding |

In real terms, replacing 100,000 units of 100ml PET bottles with PLA can offset 24,000+ kg of CO₂—equivalent to planting nearly 1,000 trees.

PauPack helps clients calculate the specific emission savings of each product line, so you can report metrics in ESG and CSR statements.

Are PLA Bottles Durable Enough for Cosmetic and Skincare Use?

PLA sounds promising—but does it perform?

Yes, PLA bottles are suitable for many personal care applications, especially non-reactive, water-based, or organic formulas that align with green brand messaging.

However, there are some limits to consider:

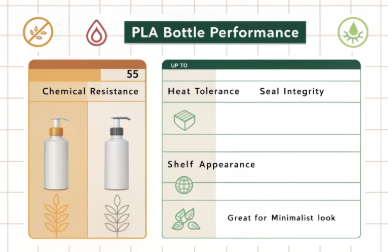

| Feature | Performance | Notes |

|---|---|---|

| Chemical Resistance | Moderate | Not ideal for alcohol or oils |

| Heat Tolerance | Up to ~55°C | Avoid hot fill or heat shipping |

| Seal Integrity | Excellent with compatible caps | Use leak-proof PP or bamboo tops |

| Shelf Appearance | High clarity, premium look | Great for minimalist branding |

At PauPack, we engineer PLA packaging for compatibility. That includes:

-

Tight neck/cap matching to prevent leaks

-

Spray, pump, or dropper caps that suit PLA threading

-

External coating options for improved durability

How PauPack Helps Brands Transition to Low-Carbon Packaging?

Switching packaging materials isn’t just a design decision—it’s an operational shift.

PauPack supports your transition with material expertise, certified supply chains, and full-service custom packaging development in PLA, PCR, and bamboo composites.

Why brands trust us:

-

One-stop support: From concept sketches to mold testing

-

Certified PLA supply: Verified low-emission feedstock

-

MOQ flexibility: Start from 1000 pcs for testing

-

Sustainability consulting: Packaging LCA support available

-

End-of-life guidance: Compostable certification, disposal labeling

Whether you’re launching an eco line or converting existing formats, we align packaging with your environmental goals—without compromising your design or cost targets.

Should You Switch to PLA in 2025? Key Factors to Consider

PLA is a compelling option—but it's not for every product.

Consider your formula, market, compliance needs, and brand mission before fully switching to PLA bottles.

Key Decision Factors

| Consideration | Question to Ask |

|---|---|

| Product Type | Is your formula PLA-compatible (non-oily, low heat)? |

| Brand Positioning | Will eco-packaging boost your brand value? |

| Regulations | Are you shipping to regions that support compostables? |

| Recycling Systems | Can you educate consumers on disposal methods? |

| Packaging Budget | Are you ready to invest in initial mold or tooling costs? |

At PauPack, we work through these questions with clients, often recommending hybrid solutions: for example, combining PLA bottles with PCR plastic caps or bamboo lids for optimal cost, carbon, and functionality balance

Why Carbon Footprint Transparency Matters in 2025 Packaging Decisions?

Your packaging’s carbon footprint is now part of your product’s identity.

In 2025, carbon transparency is a key purchasing criterion for B2B buyers, retailers, and regulators—making low-emission materials like PLA more valuable than ever.

What’s driving this shift?

-

ESG frameworks now require Scope 3 emission reporting—including packaging

-

Retailers increasingly demand packaging footprint disclosures

-

Consumers are calling out greenwashing, expecting data-backed claims

Comparative Snapshot: Carbon Emissions per Bottle (100ml unit)

| Material | Lifecycle CO₂ Emissions |

|---|---|

| PET | ~0.32 kg |

| HDPE | ~0.28 kg |

| PLA | ~0.06–0.08 kg |

At PauPack, we help our clients back up their sustainability claims with data—from material certifications to LCA (Life Cycle Assessment) reports. It’s no longer enough to say “eco-friendly”—you have to prove it.

How Do PLA Bottles Align with Global Sustainability Policies?

Choosing PLA isn’t just smart—it’s strategic for compliance.

PLA packaging aligns with global green policies such as the EU Green Deal, U.S. FTC Green Guides, and Asia’s plastic reduction mandates.

Examples of Key Regulatory Fit:

| Region | Policy | PLA Benefit |

|---|---|---|

| EU | Single-Use Plastics Directive | PLA qualifies under compostable exemptions |

| USA | State-level plastic bans (CA, NY, WA) | PLA offers plant-based alternative |

| Japan | Plastic Resource Circulation Law | Promotes bioplastics adoption |

Many of our clients now use PLA bottles with bamboo lids or PCR caps to meet dual goals: policy compliance and brand storytelling. PauPack supports this with regulatory guidance, label claims consulting, and disposal best practices.

Can PLA Packaging Compete on Cost with Traditional Plastics?

PLA used to be expensive—but that’s changing fast.

Thanks to improved sourcing, automation, and scale, PLA bottle pricing is approaching parity with traditional plastics—especially when carbon taxes and ESG costs are factored in.

Cost Analysis: PLA vs PET (2024–2025 Outlook)

| Component | PLA (per 100ml unit) | PET (per 100ml unit) |

|---|---|---|

| Base Material | $0.11–$0.15 | $0.09–$0.13 |

| Production Energy | Lower | Higher |

| Emission Cost (EU/CA) | $0 | $0.01–$0.02 |

| Disposal Fee | Compostable route | Recyclable/landfill |

PauPack reduces PLA cost through:

-

Strategic raw material partnerships

-

In-house mold library

-

Shared tooling systems for small batches

This lets clients test PLA affordably—even at MOQs as low as 1000 pcs—before committing to larger rollouts.

How PauPack Ensures Quality and Compliance in PLA Bottle Production?

PLA sounds good—but how do you ensure real-world performance?

PauPack delivers premium PLA packaging backed by third-party certification, in-house QC, and field-tested performance across cosmetic, wellness, and aromatherapy applications.

Our PLA Production Guarantees:

-

Verified biopolymer sourcing (corn/sugarcane-based, GMO-free)

-

Material certifications: EN 13432 (EU), ASTM D6400 (US)

-

Heat and pressure testing for filling, shipping, and usage

-

Tamper-proof compatibility with pumps, droppers, and spray heads

-

Design consultation to ensure PLA suitability based on formula

We’ve worked with over 200 brands to transition from PET to PLA—many of them startups needing low MOQ + fast sampling, without compromising on quality or compliance.

What Are the Long-term Benefits of Switching to PLA for B2B Brands?

PLA isn’t just a cost or compliance choice—it’s a brand strategy.

Switching to PLA can future-proof your product line by boosting ESG scores, increasing shelf appeal, and aligning with B2B retailer and distributor requirements.

Long-Term Gains from PLA Adoption

| Benefit | Description |

|---|---|

| Stronger ESG Rating | Reduces Scope 3 emissions |

| Retail Access | Meets green packaging demands from stores like Whole Foods, DM, and Boots |

| Consumer Trust | Aligns with health + eco values |

| Product Innovation | Enables storytelling around design, origin, and end-of-life strategy |

With PauPack, brands don’t just switch materials—they elevate their positioning. From laser-engraved bamboo caps to frosted PLA finishes, we help clients design packaging that’s functional, beautiful, and future-ready.

Conclusion

PLA bottles offer a clear carbon advantage—and a compelling brand story. If your 2025 packaging strategy includes lower emissions and higher trust, PauPack is your go-to partner.