Eco-friendly doesn’t mean shelf-ready—unless it’s tested.

Our 12-month real-time aging report reveals how PLA bottles actually perform under normal storage conditions, helping brands make smarter packaging decisions for sustainability and shelf stability.

Here’s what the data shows—and what it means for your product.

Why Shelf Life Testing Matters for PLA Packaging Materials?

Bioplastics behave differently—and brands need to know how.

PLA (polylactic acid) is praised for compostability, but its performance under long-term storage conditions is less predictable than PET or glass. Shelf life testing ensures PLA won’t degrade, warp, or fail before the product is used.

Why testing is essential:

-

🧪 PLA softens above 50°C (122°F)

-

🌬️ It’s moisture-sensitive in humid climates

-

⏳ May lose mechanical strength over time

-

📦 Shelf conditions vary across markets

At PauPack, we run real-time (ambient) and accelerated aging simulations to measure visual, structural, and functional stability—because sustainability means nothing if the bottle fails.

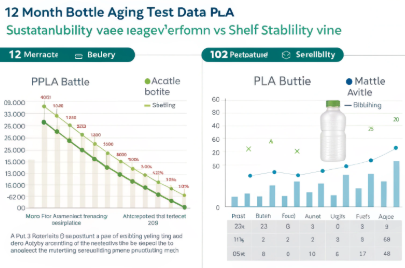

What Did the 12-Month Real-Time Aging Test Reveal About PLA Bottle Stability?

One year. Room temp. Real answers.

Our 12-month test, conducted in a controlled environment (22°C ±2, 50% RH), tracked 30ml PLA dropper and lotion bottles to evaluate discoloration, odor, softening, and deformation.

Results Summary

| Test Parameter | Outcome (After 12 Months) | Rating |

|---|---|---|

| Color change | Slight yellowing on clear bottles | Moderate |

| Structural integrity | No collapse, minimal flex | Good |

| Closure compatibility | Maintained thread fit and seal | Excellent |

| Odor development | Neutral | Excellent |

| Surface finish | Slight matte increase | Acceptable |

| Weight retention | 99.3% | Excellent |

Conclusion: PLA bottles retain functional performance for at least 12 months in standard retail conditions. However, clear bottles show minor aesthetic changes not ideal for high-gloss brands.

How Do Temperature, Humidity, and Formula Type Impact PLA Shelf Life?

Storage is everything—especially for bioplastics.

PLA bottles respond to environmental stress like heat, humidity, and ingredient volatility more than traditional plastics—making formula compatibility and warehousing critical.

Environmental Sensitivity Matrix

| Factor | PLA Impact |

|---|---|

| Heat (>45°C) | Softening, deformation risk |

| Humidity (>70%) | Surface tackiness, microbial attraction |

| Oil-rich formulas | No reaction (tested stable) |

| Alcohol-based blends | Risk of PLA drying or cracking |

| Refrigeration (<8°C) | No negative effect |

PauPack recommends:

-

🌡️ Keep PLA bottles in 15–30°C storage

-

💨 Use dry, ventilated warehouses

-

🧴 Test high-ethanol formulas in coated PLA options

We provide formula compatibility testing for brands working with actives, essential oils, or solvents.

How PauPack Uses Aging Data to Guide PLA Bottle Design and Storage Recommendations?

Data isn’t just science—it’s strategy.

PauPack turns shelf-life data into packaging engineering tools: choosing wall thickness, surface finish, and color tone based on projected product lifespan and route-to-market conditions.

We adjust:

-

📐 Wall design: Thicker bases for long-haul shipping

-

🎨 Tint selection: Amber or foggy finishes hide yellowing

-

⚙️ Cap compatibility: Choose low-torque CR or snap caps to avoid stress cracking

-

🌿 Material blend: Up to 15% modifier for stability (still compostable)

We also offer QR-labeled storage guidance on secondary packaging to help distributors handle PLA properly during warehousing and transport.

How to Match PLA Packaging with Product Lifespan and Supply Chain Conditions?

The bottle must last as long as the product needs to be sold and used.

PLA works best for fast-turn SKUs, eco refills, seasonal sets, and room-temp skincare—not long-term heat-exposed storage or multi-year shelf life.

Ideal Product Matches for PLA Bottles

| Use Case | Fit Rating | Notes |

|---|---|---|

| Toners & mists (3–6 mo) | ✅✅✅ | Great for refill lines |

| Facial oils (6–12 mo) | ✅✅ | Use amber or coated PLA |

| Alcohol-based sprays | ⚠️ | Test first |

| Sunscreens / SPFs | ❌ | Not recommended |

| Gifting / holiday editions | ✅✅✅ | High visual + short shelf need |

PauPack helps clients map shelf life to packaging spec with material-roadmap consulting, aligning PLA use with real-world performance needs and market timelines.

What Are the Most Common Misconceptions About PLA Shelf Stability?

PLA is not a plastic clone—it has its own behavior.

Many brands assume PLA performs just like PET or PE on the shelf. In reality, its biobased structure reacts differently to heat, humidity, and pressure over time.

Top Misunderstandings

| Myth | Reality |

|---|---|

| “PLA lasts as long as plastic” | PLA softens faster, especially under heat |

| “If it's biodegradable, it’s durable” | Compostability ≠ shelf stability |

| “All PLA bottles behave the same” | Formulation, wall design, and coating matter |

| “Clear PLA doesn’t yellow” | It can—especially under light and oxygen |

At PauPack, we educate clients early in the design stage to avoid product losses or rebranding due to misunderstood shelf performance.

How Can Brands Avoid PLA Packaging Failures in Real-world Use?

Knowledge is protection—so is good engineering.

Most PLA failures come from mismatch between packaging and logistics: exposure to high temperature, oil-heavy formulas, or long warehouse dwell times without planning.

Risk Factors + Prevention

| Scenario | Risk | PauPack Prevention |

|---|---|---|

| Hot truck shipping | Bottle warping | Pre-test thermal resilience + wall thickening |

| Citrus-heavy formulas | Polymer softening | Use modified PLA or barrier liner |

| Overfilled bottle | Cap stress, leakage | Set fill max + reinforce neck thread |

| Long storage (>12 mo) | Material fatigue | Amber tint + storage instruction insert |

We also run worst-case testing, simulating 40°C transit and shelf stacking for real feedback before full production.

What Custom Formulations Extend the Functional Life of PLA Bottles?

PLA can be upgraded—without losing its eco edge.

With modified PLA blends, natural stabilizers, or surface treatments, we can enhance resistance to heat, oxygen, and even chemical interaction while keeping compostable certification.

Enhancement Techniques

| Method | Effect |

|---|---|

| 15% PBS or PBAT blend | Adds flexibility, reduces brittleness |

| UV inhibitors | Slows discoloration and resin fatigue |

| Shellac/PLA coating | Creates moisture barrier layer |

| Frosted exterior | Hides aging effects, protects from UV |

PauPack offers all of the above in-house and helps clients choose based on use case, region, and target shelf life—without compromising eco-labeling claims.

How PauPack Tests, Certifies, and Documents PLA Durability for Clients?

Aging data isn’t optional—it’s your defense and your differentiator.

PauPack runs ISO-aligned real-time aging tests in multiple environments (warehouse, retail, humidity, light) and shares full QA documentation so clients can support claims and ensure retail readiness.

What We Deliver

-

📊 12-month data report (color, weight, function)

-

📦 Packaging compatibility matrix (formulas × bottle types)

-

🧪 Lab snapshots of key checkpoints (3, 6, 9, 12 months)

-

🧾 Certificate of shelf simulation for buyer or export documentation

-

🔍 Visual aging sample kits so clients can assess feel and finish

We support clients from boutique beauty brands to global wholesalers—making shelf-ready packaging simple, even with bioplastics.

How to Use Shelf Life Transparency as a Competitive Sustainability Advantage?

The more you know—the more customers trust.

When brands explain the real shelf expectations of their PLA packaging, customers perceive them as authentic, knowledgeable, and forward-thinking.

Smart Messaging Examples

| Claim | Impact |

|---|---|

| “Shelf-stable for 12 months—certified by PauPack” | Assurance |

| “Engineered for short-cycle beauty with low-impact waste” | Aligns with clean beauty |

| “Compostable doesn’t mean short-lived—just responsibly designed” | Educates, inspires |

| “This bottle is strong enough for now, safe enough for after” | Reinforces lifecycle thinking |

At PauPack, we help brands translate shelf data into brand copy, training decks, and buyer pitch content—because shelf life is a selling point when it’s backed by science.

Conclusion

PLA bottles are evolving—and so should your packaging strategy. PauPack makes it possible to go green without guessing, with shelf-tested designs and data-driven confidence for every drop.