The discourse surrounding packaging materials has become increasingly complex, driven by growing environmental awareness and the urgent need for sustainable practices across industries. Among the most pervasive and debated materials are glass and plastic. Each possesses distinct properties, production pathways, and end-of-life scenarios that contribute to their overall environmental footprint. For businesses, including our own at Paupacking, making informed decisions about packaging is not merely a matter of cost or convenience, but a fundamental aspect of corporate social responsibility and brand identity.

At Paupacking, we are dedicated to providing high-qualityGlass Bottlesthat embody both elegance and environmental stewardship. Our commitment extends beyond manufacturing to fostering a deeper understanding of sustainable packaging solutions. This comprehensive guide meticulously dissects the environmental impacts of glass and plastic packaging, offering a nuanced comparison across their entire life cycles. We will explore everything from their raw material extraction and production processes to their transportation, recyclability, and ultimate fate, aiming to provide a clear, evidence-based perspective on which material holds the environmental edge. By examining the intricate details of each, we empower consumers and businesses to make choices that align with a greener future.

1. Introduction: The Criticality of Sustainable Packaging in the Modern Era

Packaging serves a multitude of vital functions in our global economy. It protects products from damage and contamination, extends shelf life, provides crucial information to consumers, and facilitates efficient storage and distribution. However, the convenience and utility of packaging come at a significant environmental cost. The proliferation of packaging waste, the consumption of finite resources, and the associated greenhouse gas emissions contribute profoundly to climate change, pollution, and ecosystem degradation.

The growing environmental consciousness among consumers, coupled with increasingly stringent regulatory frameworks, has placed immense pressure on industries to adopt more sustainable packaging solutions. This shift necessitates a meticulous evaluation of materials, processes, and end-of-life management strategies. In this context, the seemingly straightforward question of "glass versus plastic" unfolds into a complex, multifaceted debate. Both materials have entrenched positions in various markets—from beverages and food to pharmaceuticals and cosmetics—and both present unique environmental trade-offs.

Understanding these trade-offs is paramount. A truly sustainable packaging choice minimizes negative impacts across its entire life cycle, from cradle to grave (or, ideally, to cradle again, in a circular economy model). This involves assessing factors such as raw material sourcing, manufacturing energy intensity, transportation logistics, recyclability, and potential for environmental harm once discarded. By dissecting these elements forglass bottlesand plastic containers, we can move beyond generalized assumptions and towards data-driven conclusions that inform more responsible packaging decisions. This deep dive aims to illuminate the intricate environmental profiles of these two ubiquitous materials, providing valuable insights for anyone committed to reducing their ecological footprint.

2. Production Energy and Carbon Footprint: The Manufacturing Imprint

The initial phase of any material's life cycle—its production—is a significant contributor to its overall environmental impact, primarily through energy consumption and associated carbon emissions. The manufacturing processes for glass and plastic differ substantially, leading to divergent carbon footprints at this critical stage.

Glass Production: An Energy-Intensive Process with Enduring Qualities

The creation ofglass bottlesis an inherently energy-intensive process. The primary raw materials—silica sand, soda ash, and limestone—must be melted at extremely high temperatures, typically ranging from 1425°C to 1540°C (around 2600–2800°F). This requires substantial amounts of energy, predominantly derived from fossil fuels, which leads to significant carbon dioxide (CO2) emissions. In addition to the energy used for melting, CO2 is also released as a byproduct of the chemical reactions involved in heating limestone and soda ash. Industry life cycle assessments consistently show that producing just one gram of virgin glass emits approximately 3.0 grams of CO2. This figure underscores the substantial carbon footprint associated with new glass manufacturing.

Furthermore,glass bottlesare generally heavier and thicker than their plastic counterparts to ensure sufficient strength and durability for various applications, especially for holding carbonated beverages or for reuse. This means that a single glass container requires more raw material input by weight, which compounds its initial carbon footprint. For instance, a common glass jar used for food or beverages might weigh 82 grams. Based on the 3.0 g CO2 per gram of glass, the production of this single jar alone would generate roughly 246 grams of CO2 emissions. While the intrinsic qualities of glass, such as its inertness and perceived premium feel, are highly valued, its manufacturing process undeniably demands a considerable energy investment. The commitment from manufacturers like Paupacking to optimize production efficiency and increase recycled content is crucial for mitigating this initial environmental burden.

Plastic Production: Lower Energy Demand but Fossil Fuel Dependency

In stark contrast, the production of plastic bottles, particularly those made from polyethylene terephthalate (PET)—the most common type for beverages—is considerably less energy-intensive than glass manufacturing. The polymerization process, which converts raw monomers into plastic polymers, and the subsequent molding into bottle shapes, operate at much lower temperatures, typically between 200°C and 260°C (400–500°F). This lower temperature requirement translates directly into reduced energy consumption during the manufacturing phase. On average, producing one gram of PET plastic emits approximately 3.8 grams of CO2.

While this per-gram CO2 emission figure might appear higher than glass, the critical difference lies in the weight of the final product. Plastic bottles are significantly lighter thanglass bottlesof comparable volume. A plastic jar weighing only 13 grams, for example, would generate about 49 grams of CO2 during its production. This represents a mere 20% of the carbon impact of an 82-gram glass jar. This substantial disparity at the production stage gives plastic a distinct advantage in terms of initial carbon footprint. However, it is crucial to remember that plastic production is overwhelmingly dependent on fossil fuels—petroleum or natural gas—as its primary feedstock. This reliance on finite, non-renewable resources raises long-term sustainability concerns, regardless of the immediate energy efficiency of the manufacturing process. The debate, therefore, extends beyond mere energy consumption to the broader implications of resource depletion and reliance on carbon-intensive raw materials.

Summary: A Stark Contrast in Production Footprints

The comparison of production energy and carbon footprint reveals a clear difference:

| Material | Energy Use (Relative) | CO2 Emissions (per gram of material) | Typical Bottle Weight (Example) | Total CO2 per Bottle (Example) | Primary Raw Material Dependency |

|---|---|---|---|---|---|

| Glass | High | 3.0 g | 82 g | 246 g | Silica sand, soda ash (mined) |

| Plastic | Moderate | 3.8 g | 13 g | 49 g | Fossil fuels (petroleum/natural gas) |

3. Transportation Impact: The Weighty Consequence of Logistics

Beyond the manufacturing floor, the environmental footprint of packaging is significantly influenced by its journey from producer to consumer. In this regard, the physical properties of the material, particularly its weight, play a pivotal role in determining transportation emissions.

The inherently heavier nature ofglass bottlestranslates directly into a higher environmental cost during logistics. A single one-liter glass bottle, for instance, can weigh as much as 800 grams. In stark contrast, a plastic bottle of the same volume typically weighs around 40 grams. This substantial weight differential has profound implications for fuel consumption and greenhouse gas emissions during transportation.

Heavier loads mean that transport vehicles, primarily trucks, can carry fewer units per trip. Consequently, more trips are required to move the same volume of product when packaged in glass compared to plastic. This increased number of journeys directly correlates with higher fuel consumption and, by extension, greater CO2 emissions released into the atmosphere. Studies comparing various packaging materials consistently highlight this disadvantage for glass. For example, some analyses suggest thatglass bottlescan contribute approximately 95% more to the global warming potential due to transport inefficiencies compared to much lighter aluminum cans, and significantly more than plastic bottles. The emissions associated with transporting glass can, in some cases, even outweigh the environmental benefits derived from its recyclability, especially over long distances.

For companies like Paupacking, while ourGlass Bottlesare crafted for durability and aesthetic appeal, the inherent weight of glass remains a critical factor in the overall environmental footprint. Optimizing supply chains, sourcing raw materials locally where possible, and strategically locating manufacturing facilities closer to markets can help mitigate these transportation-related emissions. However, the fundamental physical properties of glass mean that it will always present a greater logistical challenge, and thus a higher transportation-related environmental burden, than lighter packaging alternatives like plastic. This aspect underscores the complexity of environmental assessments, where benefits in one life cycle stage can be offset by detriments in another.

4. Recyclability and Circular Economy: Closing the Loop?

The ability of a material to be recycled and reintegrated into the production cycle is a cornerstone of the circular economy model, which aims to minimize waste and maximize resource efficiency. Both glass and plastic are recyclable, but their respective recycling processes, challenges, and outcomes differ significantly.

Glass: Infinitely Recyclable, But Not Without Hurdles

Glass is heralded as a champion of recyclability, and for good reason. It is 100% recyclable, meaning it can be melted down and reformed into newglass bottlesor other glass products repeatedly without any loss of quality or purity. This characteristic positions glass as an ideal material for a truly closed-loop system, where virgin raw material extraction can be significantly reduced. Recycling glass also offers substantial energy savings: using cullet (recycled glass) in the furnace requires less energy than melting virgin raw materials, often quoted as saving around 25-30% of the energy and reducing CO2 emissions by up to 50% for every 10% of cullet used. This translates to lower overall environmental impact in the subsequent production cycles.

However, the practical realities of glass recycling present several challenges. Firstly, recycling rates for glass vary considerably across different regions and countries, largely dependent on the robustness of collection infrastructure and public participation in recycling programs. Many areas lack efficient curbside collection for glass, often relying on drop-off points, which can deter consistent recycling efforts. Secondly,glass bottlesare inherently fragile. Breakage during collection, sorting, and transportation can lead to contamination of other recyclable materials (such as paper and plastic) and reduces the amount of usable cullet. Mixed-color glass or glass contaminated with ceramics, stones, or porcelain (CSP) can also diminish the quality of recycled material, limiting its use in new high-grade packaging. Despite these operational hurdles, the fundamental chemical stability and infinite recyclability of glass make it a highly desirable material for a circular economy, provided effective collection and processing systems are in place. For Paupacking, our commitment to using recycled content in ourGlass Bottlesis a testament to this inherent recyclability and our dedication to sustainability.

Plastic: High Potential, but Quality Degradation and Systemic Challenges

Plastic, particularly PET (polyethylene terephthalate) which is widely used for beverage containers, boasts a high potential for recycling. PET is the most commonly recycled plastic, with well-established collection and processing streams in many parts of the world. However, unlike glass, plastic experiences a degradation in quality with each recycling cycle. This phenomenon, known as "downcycling," means that recycled plastic often has inferior physical properties compared to virgin plastic. For instance, a plastic bottle recycled into a new bottle often requires virgin plastic to maintain strength and clarity, or it might be downcycled into less demanding applications like carpet fibers, insulation, or park benches, eventually reaching its end-of-life without further recycling. This gradual loss of quality means plastic does not currently support a truly closed-loop system in the same way glass does for its primary application (bottles back into bottles) without significant technological interventions.

Furthermore, despite its high potential, plastic recycling rates globally often lag behind those of glass in many regions. This is attributable to several factors: the vast diversity of plastic types (making sorting complex), contamination issues (food residue, non-recyclable materials), and the economic viability of recycling compared to producing virgin plastic from cheap fossil fuels. The sheer volume of plastic produced annually also overwhelms recycling capacities in many areas, leading to significant amounts ending up in landfills or polluting natural environments. While advancements in chemical recycling and the development of new bioplastics are promising avenues for improving plastic's circularity, the current linear "take-make-dispose" model remains dominant for much of the world's plastic output. The ability of Paupacking to offer robustGlass Bottlesthat are endlessly recyclable underscores a significant environmental advantage over the current state of plastic recycling.

5. Environmental Pollutants and Waste Management: The End-of-Life Story

The ultimate environmental fate of packaging materials once they are discarded is a critical aspect of their sustainability profile. This encompasses their potential to become pollutants, their persistence in the environment, and the challenges they pose for waste management systems.

Glass: Non-Toxic, Inert, but Landfill Bulky

One of the most significant environmental advantages ofglass bottlesis their chemical inertness and non-toxicity. Glass is made from natural materials and does not leach harmful chemicals or microparticles into its contents or the environment. This makes it a preferred choice for sensitive products, such as food, beverages, and pharmaceuticals, where chemical interaction with the packaging must be avoided.

When glass does end up in landfills, it is remarkably stable. It does not decompose, biodegrade, or react with other materials. While this means it doesn't break down into harmful substances, it also means that glass persists indefinitely as physical waste. The inert nature, combined with its weight and volume, contributes to the bulk of landfill waste. Unlike plastic, however, glass does not fragment into microplastics that can permeate ecosystems and enter food chains. This stability means that, while it consumes landfill space, it doesn't actively contribute to the ongoing chemical pollution or microparticle contamination that plagues terrestrial and aquatic environments. The challenge with glass in waste management lies primarily in its weight and the resource expenditure (energy) required to produce it, rather than its potential as a toxic or persistent pollutant. The use of Paupacking'sGlass Bottlessupports a non-toxic packaging solution for a range of products.

Plastic: Persistent Pollution and the Microplastics Crisis

In stark contrast, plastic pollution represents one of the most pressing environmental crises of our time. Plastic packaging, while initially offering benefits like lightweight design and durability, presents severe challenges at its end-of-life.

-

Persistence:Most conventional plastics are designed to be durable and resistant to degradation, meaning they can persist in the environment for hundreds, if not thousands, of years. This long lifespan contributes to the ever-growing accumulation of plastic waste in landfills, oceans, and natural landscapes.

-

Fragmentation and Microplastics:Instead of biodegrading, plastic typically breaks down into smaller and smaller pieces over time due to exposure to UV light, physical abrasion, and chemical processes. These microscopic fragments, known as microplastics (and even nanoplastics), are now ubiquitous in virtually every ecosystem on Earth, from the deepest oceans to the highest mountains, and even in the air we breathe and the food we eat. Microplastics pose significant threats to wildlife, leading to ingestion, entanglement, and potential physiological harm. The long-term effects on human health from microplastic exposure are still being researched but are a growing concern.

-

Chemical Leaching:While many plastics are deemed food-safe, concerns exist about the potential for certain chemicals (e.g., plasticizers like phthalates, BPA substitutes) to leach from plastic packaging into food and beverages, especially under certain conditions like heat or prolonged storage.

-

Waste Management Burden:The sheer volume and diversity of plastic waste (different polymers require different recycling processes) overwhelm global waste management systems. Much of the plastic collected for recycling is either contaminated or lacks viable end markets, leading to it being landfilled, incinerated, or, unfortunately, illegally dumped.

The global crisis of plastic waste, particularly marine plastic pollution, highlights the profound environmental consequences of a material that, despite its initial production advantages, poses significant long-term ecological risks once discarded. This profound difference in end-of-life impact is a critical factor when evaluating the overall environmental friendliness of glass versus plastic. Paupacking's decision to focus onGlass Bottlesoffers a compelling alternative to materials contributing to persistent pollution.

6. Water and Resource Consumption: A Deeper Dive into Raw Materials

Beyond energy and waste, the consumption of natural resources, including water and raw materials, forms another crucial dimension of a packaging material's environmental footprint. Both glass and plastic production demand significant resources, albeit different types.

The production ofglass bottlesfundamentally relies on abundant natural raw materials: silica sand, soda ash, and limestone. These minerals are extracted through mining operations, which can have localized environmental impacts, including habitat disruption and dust pollution. While these raw materials are generally plentiful, their extraction and subsequent processing (grinding, mixing) contribute to the overall environmental burden. Furthermore, the energy-intensive melting process for glass consumes substantial amounts of water, primarily for cooling purposes within the manufacturing facilities. While water is typically recycled within the plant, the initial withdrawal and subsequent treatment processes still represent a significant resource demand.

In contrast, plastic production is heavily dependent on fossil fuels—petroleum or natural gas—as its primary feedstock. These non-renewable resources are extracted through drilling, which can have far-reaching environmental consequences, including habitat destruction, water pollution, and greenhouse gas emissions associated with extraction and transportation. The chemical conversion of these fossil fuels into plastic polymers is a complex industrial process. However, when compared to glass manufacturing, the actual plastic manufacturing process (polymerization and molding) typically uses less water. This is because the primary energy input is chemical conversion rather than high-temperature melting that requires extensive cooling. Despite the lower water usage during manufacturing, the fundamental reliance on finite fossil fuels positions plastic at a disadvantage from a long-term resource depletion perspective. The burgeoning interest in bioplastics, derived from renewable biomass sources, aims to address this dependency, but these alternatives currently constitute a very small fraction of global plastic production. Paupacking, through its emphasis onGlass Bottles, aligns with a material derived from abundant natural minerals, reducing reliance on fossil fuels for its base composition.

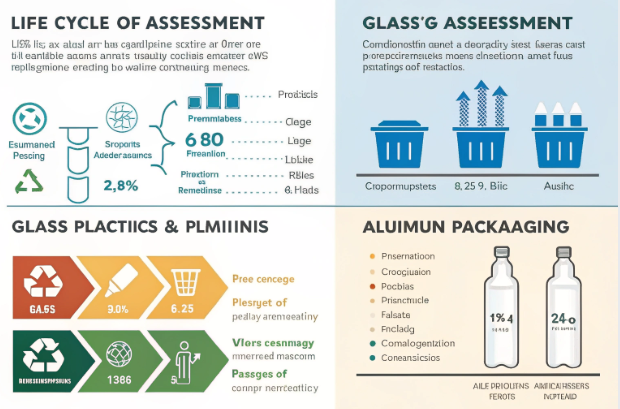

7. Life Cycle Assessment (LCA) Findings: What the Studies Tell Us

Life Cycle Assessment (LCA) is a standardized methodology used to evaluate the environmental impacts of a product, process, or service throughout its entire life cycle, from raw material extraction ("cradle") to disposal or recycling ("grave"). LCAs are complex and require detailed data, but they offer the most comprehensive approach to comparing the environmental performance of different materials. When comparingglass bottles, plastic, and other alternatives like aluminum, LCAs often reveal nuances that challenge common perceptions.

Recent, comprehensive LCAs focused on beverage containers have frequently highlighted the surprising environmental performance of different materials across various metrics:

-

PET Plastic Bottles:Many LCAs conclude that PET plastic bottles often have the lowest overall environmental impact across multiple categories, including greenhouse gas emissions, cumulative energy demand, and water consumption. This seemingly counter-intuitive finding is largely driven by plastic's significantly lower weight, which translates to substantially reduced transportation emissions throughout the supply chain. Despite its fossil fuel origin and end-of-life challenges, the efficiency in production and transport often gives PET an advantage in carbon footprint and energy use over a single life cycle compared to glass.

-

Glass Bottles:LCAs typically place glass bottles at the higher end of the environmental impact spectrum. This is predominantly due to their energy-intensive manufacturing process (requiring very high temperatures for melting raw materials) and their heavier weight, which incurs significantly higher transportation emissions. While glass's infinite recyclability is a major benefit, the energy required for initial production and the logistics burden often offset some of these advantages in a single-use LCA context, especially if recycled content is low or if transportation distances are long. However, it's crucial to consider that LCAs often struggle to fully account for the long-term environmental persistence and microplastic issues associated with plastic pollution, which glass does not exhibit. The inertness and non-toxic nature ofglass bottlesare often difficult to quantify adequately in standard LCA metrics.

-

Aluminum Cans:Aluminum cans typically fall somewhere between plastic and glass in terms of overall environmental impact. They require substantial energy for virgin aluminum production but are very lightweight and highly recyclable, with high recycling rates in many regions.

For instance, a 2023 study by NAPCOR (The National Association for PET Container Resources) commissioned a comparative LCA which found that switching from glass to PET bottles for common soda beverages could lead to significant reductions across various environmental impact categories, including greenhouse gas emissions, water usage, and solid waste generation. These findings underscore the importance of considering the entire life cycle, not just isolated aspects like recyclability, when assessing environmental performance.

However, it is vital to approach LCA results with critical discernment. LCAs depend heavily on the specific methodologies, data inputs, and assumptions made (e.g., recycling rates, transport distances, energy mixes). They may not always fully capture complex issues like ocean plastic pollution, microplastic formation, or the aesthetic and inertness benefits of glass that influence consumer choice and product integrity. While LCAs provide valuable data-driven insights into quantifiable impacts like energy consumption and emissions, the broader environmental narrative is more complex. Paupacking remains committed to providing transparent information about ourGlass Bottlesand their environmental profile, recognizing that sustainability is a continuous journey of improvement.

8. Practical Considerations: Beyond Pure Environmental Metrics

Beyond the strictly environmental metrics quantified by LCAs, several practical considerations influence the choice betweenglass bottlesand plastic, impacting both manufacturers and consumers. These factors relate to product protection, consumer perception, market trends, and logistical realities.

Durability and Safety

From a practical standpoint, plastic bottles generally offer superior durability and safety compared to glass. Plastic is lightweight and shatterproof, making it less prone to breakage during manufacturing, filling, transportation, and consumer handling. This reduces product loss, minimizes clean-up efforts in case of spills, and poses less risk of injury from broken glass. Its lighter weight also contributes to easier portability for consumers, a significant factor for on-the-go beverages and food products.

Glass bottles, while robust in terms of material strength, are inherently brittle. They are susceptible to breakage from impacts or thermal shock. This fragility necessitates more protective packaging during transit, often leading to increased material use (e.g., cardboard dividers, bubble wrap) and higher costs. The risk of breakage also influences consumer convenience, particularly for products intended for outdoor activities, children, or environments where broken glass could be hazardous. However, for certain applications, such as high-pressure carbonated beverages or products requiring complete inertness, the structural integrity and chemical stability of thickerglass bottlesfrom reputable suppliers like Paupacking are paramount. OurGlass Bottlesare designed with optimal wall thickness and consistency to balance durability with aesthetic appeal.

Consumer Perceptions and Brand Image

Consumer perception plays a significant role in packaging choices. Glass is often perceived as premium, elegant, and of higher quality. Its clarity, weight, and cool touch convey a sense of luxury, purity, and authenticity. This makesglass bottlesa preferred choice for high-end spirits, wines, gourmet foods, and natural or organic products, where the packaging is integral to the brand's image and perceived value. Consumers also tend to trust glass for its inertness, believing it best preserves the taste and integrity of the product without chemical leaching, even if this is not always a scientifically proven differentiator for all plastic types. The aesthetic appeal ofglass bottlescan significantly enhance a product's shelf presence and appeal to consumers willing to pay a premium for perceived quality and sustainability.

Plastic, on the other hand, is widely associated with convenience, affordability, and lightness. While it may not carry the same premium aura as glass, its practical advantages make it highly appealing for mass-market products, especially those where portability and cost-effectiveness are key. However, the pervasive issue of plastic pollution has increasingly tarnished plastic's image, leading to a growing segment of consumers who actively seek alternatives. Brands that choose plastic are often facing pressure to demonstrate their commitment to plastic recycling and reduction strategies. Paupacking understands this duality, and ourGlass Bottlesare specifically designed to cater to brands that wish to leverage the premium image and perceived environmental benefits associated with glass.

Cost Implications

The cost of packaging is a major practical consideration for businesses. Generally,glass bottlestend to be more expensive to produce and transport than plastic bottles due to their higher raw material requirements (by weight), more energy-intensive manufacturing process, and greater shipping costs. The need for more robust secondary packaging to prevent breakage further adds to the overall cost.

Plastic's lower material cost (often derived from byproducts of the oil and gas industry), lighter weight, and more efficient production processes often result in a lower unit cost for packaging. This economic advantage is a significant driver for plastic's widespread adoption, particularly in high-volume, low-margin product categories. However, these cost calculations are evolving as the true environmental costs of plastic pollution become more apparent, and as regulations (e.g., plastic taxes, extended producer responsibility schemes) aim to internalize some of these external environmental costs. The long-term cost benefits of a circular glass economy, where the material retains its value indefinitely, also need to be factored into strategic decision-making.

Ultimately, the choice between glass and plastic involves a complex balancing act of environmental impact, practical considerations like durability and logistics, consumer perceptions, and cost. While LCAs provide crucial scientific data, real-world application requires integrating these broader practical factors into the decision-making process. Paupacking's range ofGlass Bottlesoffers a solution that appeals to brands prioritizing premium aesthetics and inherent material benefits, understanding that this choice comes with its own set of practical trade-offs.

9. Innovations and Future Trends: Towards a More Sustainable Future

The packaging industry is not static; it is undergoing continuous innovation driven by environmental imperatives, technological advancements, and evolving consumer demands. Both glass and plastic packaging are subject to significant research and development efforts aimed at mitigating their respective environmental drawbacks.

Forglass bottles, key innovations focus on reducing their weight and increasing their recycled content to minimize the high energy consumption and transportation emissions associated with virgin glass production:

-

Lightweight Glass:Manufacturers are continuously developing technologies to produce thinner, yet equally strong, glass containers. This involves advanced material science, precision molding techniques, and optimized designs. Lightweighting reduces the amount of raw material used, decreases energy consumption during melting, and significantly lowers transportation emissions. While the physical properties of glass set a limit to how light it can become compared to plastic, even marginal weight reductions across millions of units can yield substantial environmental benefits.

-

Increased Recycled Content (Cullet):The industry is striving to incorporate higher percentages of cullet (recycled glass) into newglass bottles. As previously discussed, using cullet dramatically reduces the energy required for melting and lowers CO2 emissions. Challenges remain in obtaining sufficient quantities of high-quality, color-sorted cullet, but investments in advanced sorting technologies and improved collection systems are making higher recycled content rates more achievable. Paupacking is committed to leveraging advanced manufacturing techniques to produceGlass Bottleswith increasing levels of recycled content.

-

Reusable and Refillable Systems:A significant trend, particularly for glass, is the resurgence of reusable and refillable packaging models. This involves collecting, washing, and refillingglass bottlesmultiple times before they are eventually recycled. This system drastically reduces the need for new packaging production and minimizes waste, making it one of the most environmentally friendly approaches when effectively implemented.

-

Bio-based Coatings and Strengthening:Research into applying bio-based or ultra-thin ceramic coatings to glass aims to increase its strength and reduce breakage, further extending its lifespan and utility.

For plastic packaging, innovations primarily focus on addressing its end-of-life challenges and its reliance on fossil fuels:

-

Bioplastics:These are plastics derived from renewable biomass sources (e.g., corn starch, sugarcane, cellulose) rather than fossil fuels. While offering a potential reduction in carbon footprint at the raw material stage, not all bioplastics are biodegradable or compostable, and their environmental benefits depend heavily on production methods and end-of-life management.

-

Chemical Recycling:This advanced recycling technology breaks down plastic polymers into their original monomers or other chemical components, which can then be used to create new, virgin-quality plastic. Chemical recycling has the potential to overcome the downcycling limitations of mechanical recycling and process mixed or contaminated plastics that are currently unrecyclable. However, the technology is still in its nascent stages, requires significant investment, and its energy footprint is a subject of ongoing study.

-

Improved Mechanical Recycling:Efforts are continuously being made to enhance traditional mechanical recycling processes through better sorting technologies (e.g., AI-powered optical sorters), improved washing and flaking, and de-contamination processes to produce higher-quality recycled plastic that can be used in a wider range of applications, including food-grade packaging.

-

Design for Recyclability:Brands are increasingly designing plastic packaging with recyclability in mind, avoiding problematic materials, multiple layers, and non-recyclable labels or closures that can contaminate recycling streams.

The future of sustainable packaging is likely to be diverse, leveraging the strengths of multiple materials while actively mitigating their weaknesses. The ongoing innovations in both glass and plastic production and recycling technologies are crucial steps towards a more circular and environmentally responsible packaging landscape. Paupacking continues to monitor these developments to ensure ourGlass Bottlesremain at the forefront of sustainable and high-performance packaging solutions.

10. Conclusion: Navigating the Complexities of Sustainable Packaging

The debate between glass and plastic packaging is far from straightforward. There is no single, universally "more environmentally friendly" answer, as the preferred choice often depends on the specific product, its supply chain, consumer behavior, and the available waste management infrastructure. Both materials present a unique set of environmental advantages and disadvantages across their life cycles.

Glass bottlesexcel in their infinite recyclability without loss of quality, their chemical inertness (preventing leaching into products), and their premium aesthetic appeal. These qualities make them an excellent choice for preserving product integrity and conveying a sense of quality and sustainability. However, glass production is energy-intensive, and its heavier weight contributes significantly to transportation emissions, especially over long distances. The fragility of glass also poses practical challenges in handling and potential for breakage. Paupacking's commitment to producing high-qualityGlass Bottlesfocuses on maximizing these inherent benefits while working towards solutions that mitigate the material's heavier carbon footprint through sustainable practices like increasing recycled content.

Plastic, particularly PET, offers advantages in its lower initial production energy (due to lighter weight and less demanding processes) and significantly reduced transportation emissions. Its durability and lightness make it highly practical and cost-effective for mass-market products. However, plastic's reliance on finite fossil fuels for raw materials, its propensity to fragment into persistent microplastics, and the systemic challenges in achieving true circularity (due to quality degradation in recycling and low overall recycling rates) present formidable environmental hurdles. The global plastic pollution crisis underscores the urgent need to address these end-of-life issues.

Ultimately, making an environmentally responsible packaging choice requires a holistic approach, considering all phases of a material's life cycle. For brands, this means:

-

Conducting LCAs:To understand the specific impacts for their product and supply chain.

-

Prioritizing Reuse:Implementing reusable or refillable systems where feasible.

-

Maximizing Recycled Content:Choosing packaging with high levels of post-consumer recycled material.

-

Supporting Recycling Infrastructure:Advocating for and investing in improved collection and processing systems.

-

Considering End-of-Life:Selecting materials that minimize long-term environmental persistence and pollution.

Paupacking believes in empowering businesses with choice. Our premiumGlass Bottlesare designed for brands that prioritize product integrity, a premium consumer experience, and a commitment to infinitely recyclable, inert materials. While acknowledging the complexities of environmental assessment, we remain confident in the intrinsic value and long-term sustainability potential of glass within a well-managed circular economy.

The journey towards truly sustainable packaging is ongoing, driven by continuous innovation and collective responsibility. By understanding the intricate environmental profiles of glass and plastic, we can all contribute to a greener, more sustainable future for packaging.

Summary Table: Environmental Comparison of Glass vs Plastic Bottles

| Factor | Glass Bottles | Plastic Bottles | Paupacking's Approach forGlass Bottles |

|---|---|---|---|

| Production Energy & CO2 | High energy, high CO2 from melting | Lower energy, moderate CO2 from polymerization | Optimizing processes, increasing recycled content to reduce footprint |

| Weight & Transport Impact | Heavy, higher fuel consumption, more emissions | Lightweight, lower transport emissions | Designing for optimal strength-to-weight ratio, promoting local sourcing where applicable |

| Raw Material Source | Abundant minerals (sand, soda ash, limestone) | Finite fossil fuels (petroleum/natural gas) | Utilizing abundant natural resources, reducing reliance on fossil fuels |

| Recyclability | 100% recyclable, infinite cycles (no quality loss) | Recyclable but quality degrades (downcycling) | Committed to 100% recyclability, actively promoting circular economy for glass |

| Environmental Pollution | Non-toxic, inert, stable in landfill; no microplastics | Persistent pollution, microplastics, potential leaching | Providing inert, non-toxic packaging that doesn't contribute to microplastic pollution |

| Water Consumption | Moderate to High (cooling during melting) | Lower (during manufacturing) | Implementing water-efficient production and recycling practices |

| Consumer Perception | Premium, elegant, pure, often perceived as eco-friendly | Convenient, practical, cost-effective; increasing negative perception due to pollution | Delivering premium, aesthetically appealing bottles that enhance brand image and trust |

| Durability & Safety | Fragile, requires careful handling | Shatterproof, portable | Ensuring robust design and quality control to minimize breakage and enhance product safety |

| Innovation & Future | Lightweighting, increased cullet, reuse systems | Bioplastics, chemical recycling, improved mechanical recycling | Investing in lightweighting, higher recycled content, and supporting reuse models |

Paupacking's commitment to quality and sustainability ensures that ourGlass Bottlesremain a leading choice for brands prioritizing environmental responsibility without compromising style or function. We invite you to explore our collection and partner with us in advancing sustainable packaging solutions for a greener future.