Glass bottles are an essential part of packaging across many industries, from food and beverage to cosmetics and pharmaceuticals. Their timeless appeal, combined with practical benefits like durability and recyclability, makes them a preferred choice for manufacturers and consumers alike. Paupacking, as a leading supplier, offers a wide range of premiumGlass Bottlesdesigned to meet diverse needs with elegance and functionality.

This comprehensive article delves deeply into what glass bottles are made of, the manufacturing process, and the extensive variety of bottle shapes and types available. It also highlights the advantages of glass bottles and why Paupacking’s products stand out in the market. The detailed exploration aims to provide businesses and consumers with the knowledge to choose the right glass bottle for their products or personal use.

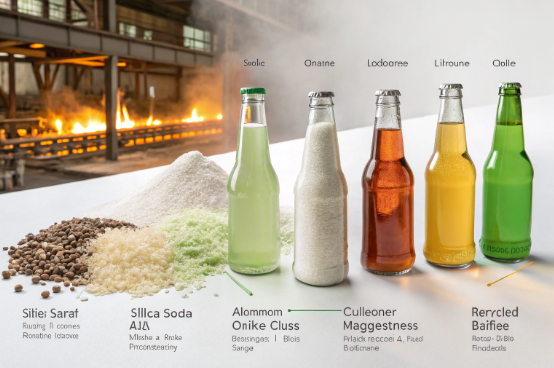

What Are Glass Bottles Made Of?

Glass, at its core, is a non-crystalline, amorphous solid primarily composed of silica (silicon dioxide). The manufacturing of glass bottles involves melting a precise blend of raw materials at extremely high temperatures to create molten glass that can be molded into various shapes. The composition and quality of the raw materials directly affect the properties of the finished glass bottle, such as clarity, strength, and chemical resistance.

Main Raw Materials in Glass Bottle Production

The primary ingredients used in making glass bottles include:

-

Silica Sand (SiO₂):Constituting about 70-75% of the glass batch, silica sand is the fundamental building block of glass. It provides the glass’s structural framework and transparency. The purity of silica sand is crucial; impurities can cause discoloration or weaken the glass.

-

Soda Ash (Sodium Carbonate, Na₂CO₃):Making up approximately 12-15%, soda ash lowers the melting point of silica, facilitating the glass-forming process. It also helps improve the glass’s workability during manufacturing.

-

Limestone (Calcium Carbonate, CaCO₃):Around 10-15% of the mix, limestone adds chemical durability and hardness to the glass. It prevents the glass from dissolving in water and improves its resistance to environmental factors.

-

Aluminum Oxide (Al₂O₃):Added in smaller quantities, aluminum oxide enhances the glass’s hardness and resistance to chemical corrosion, contributing to the bottle’s longevity.

-

Magnesium Oxide (MgO):This component improves the glass’s durability and resistance to weathering, ensuring the bottle can withstand temperature variations and handling.

-

Cullet (Recycled Glass):Incorporating cullet into the batch reduces raw material consumption and energy use. Using recycled glass also aligns with sustainable manufacturing practices.

The precise ratios of these materials are carefully controlled to produce glass with the desired characteristics for bottle manufacturing.

Types of Glass Used in Bottle Manufacturing

Different types of glass are used depending on the application and required properties of the bottle:

-

Soda-Lime Glass:This is the most common type of glass used for bottles. It is cost-effective and has good chemical stability and mechanical strength. Soda-lime glass is typically used for beverage bottles, food containers, and many household products. Paupacking’sGlass Bottlesprimarily utilize high-quality soda-lime glass to ensure clarity and durability.

-

Borosilicate Glass:Known for its exceptional resistance to thermal shock and chemical corrosion, borosilicate glass contains boron oxide. It is commonly used for laboratory glassware and high-end bottles that require heat resistance, such as certain cosmetic and pharmaceutical containers.

-

Lead Glass (Crystal):This glass contains lead oxide, which increases its refractive index and brilliance, giving it a sparkling appearance. Lead glass is mainly used for decorative bottles and luxury packaging.

-

Specialty Glass:This category includes glasses with added elements for UV protection, color, or enhanced durability. For example, amber or cobalt blue glass bottles protect light-sensitive contents from UV degradation.

Paupacking offers a variety of glass types tailored to specific industry needs, ensuring optimal performance and aesthetics.

Manufacturing Process of Glass Bottles

The production of glass bottles is a sophisticated process that combines science and artistry. It involves several critical steps designed to transform raw materials into flawless containers.

-

Batch Mixing:Raw materials are precisely weighed and mixed according to the glass formula. This mixture is called the batch.

-

Melting:The batch is heated in a furnace at temperatures exceeding 1,500°C (2,732°F) until it melts into a homogeneous molten glass. This step requires careful temperature control to ensure uniformity.

-

Forming:The molten glass is shaped into bottles using techniques such as blow-and-blow or press-and-blow. In the blow-and-blow method, a gob of molten glass is first formed into a parison (a preliminary bottle shape) and then blown into the final mold. Press-and-blow involves pressing the glass into a parison mold before blowing it into the final shape.

-

Annealing:Bottles are gradually cooled in an annealing oven (lehr) to relieve internal stresses. This step is crucial to prevent cracking or breaking during handling.

-

Inspection:Each bottle undergoes rigorous inspection for defects such as bubbles, cracks, or irregularities. Automated systems and manual checks ensure quality.

-

Finishing:Bottles may receive surface treatments, coatings, or labeling. Closures such as caps or corks are fitted according to the product requirements.

Paupacking’s manufacturing process adheres to strict quality standards, ensuring everyGlass Bottlecombines durability with flawless design.

Different Types of Glass Bottles

Glass bottles come in a vast array of shapes and sizes, each designed to meet specific functional and aesthetic requirements. Below is an in-depth look at the most common glass bottle types, their characteristics, and typical applications.

1. Round Bottles

Round bottles are the most classic and widely used glass bottle shape. Their cylindrical form maximizes storage efficiency and shelf space while providing a smooth, ergonomic surface that is easy to handle.

The round shape is ideal for a broad range of products, including beverages like water, juices, spirits, and oils. The absence of corners reduces the risk of breakage during transport and handling. Paupacking’sGlass Bottlesin round shapes are designed with clarity and strength, ensuring they meet the demands of various industries.

Round bottles also offer excellent branding opportunities, as labels can wrap around the surface seamlessly, allowing for creative design and marketing.

2. Square Bottles

Square bottles feature flat sides and sharp edges, offering a distinctive geometric look that stands out on shelves. Their shape is highly space-efficient, allowing for compact packing and storage, which is advantageous for both retailers and consumers.

Square bottles are often used for spirits, perfumes, and specialty food products. Their flat surfaces provide ample space for branding and labeling, making them popular for premium product lines. Paupacking’s square glass bottles combine modern aesthetics with practical design, providing a sleek and sturdy packaging solution.

The angular design also facilitates better grip, reducing the chance of slipping during use.

3. Oval Bottles

Oval bottles blend the smooth curves of round bottles with a flattened profile, resulting in a sleek and elegant shape. This design is often chosen for luxury goods and cosmetic products due to its sophisticated appearance.

The ergonomic shape of oval bottles makes them comfortable to hold and use. They are commonly used for perfumes, lotions, and high-end beverages, where both form and function are critical. Paupacking’s oval glass bottles offer a refined look that enhances product appeal.

The flattened sides also provide an excellent canvas for decorative printing or embossing.

4. Rectangular Bottles

Rectangular bottles present a contemporary and practical design with flat surfaces and sharp edges. Their shape is ideal for maximizing shelf space and providing a modern look.

These bottles are widely used in pharmaceuticals, personal care, and specialty beverages. The flat surfaces make them perfect for labels and branding, allowing for clear product information display. Paupacking’s rectangular glass bottles balance style and utility, making them a versatile choice for various industries.

Their shape also lends itself well to stacking and efficient packing during shipping.

5. Boston Round Bottles

Boston round bottles are characterized by their rounded shoulders and cylindrical bodies. This classic shape is a staple in the pharmaceutical, essential oil, and cosmetic industries.

The design facilitates easy pouring and dispensing, often paired with droppers, spray caps, or screw tops. Paupacking’s Boston round glass bottles are manufactured with precision to ensure compatibility with various closures and maintain product integrity.

Their timeless design also conveys reliability and professionalism, making them popular for medicinal and wellness products.

6. Long-Necked Bottles

Long-necked bottles feature an extended neck that helps control pouring and reduces spillage. This shape is commonly associated with beverages such as wine, beer, and spirits.

The elongated neck adds elegance and functionality, allowing for controlled flow and easy handling. Paupacking’s long-necked glass bottles combine aesthetic refinement with robustness, suitable for premium beverage packaging.

These bottles often incorporate decorative elements like embossing or colored glass to enhance brand identity.

7. Specialty-Shaped Bottles

Specialty-shaped bottles are custom-designed to reflect a brand’s identity or the uniqueness of a product. These bottles can feature artistic curves, embossed logos, or unconventional shapes that differentiate products on crowded shelves.

Paupacking offers bespoke glass bottle design services, enabling clients to create distinctive packaging that aligns with their marketing strategies. Specialty bottles are popular in luxury spirits, perfumes, and artisanal food products.

The ability to customize shape, color, and finish allows brands to tell their story through packaging.

Advantages of Glass Bottles

Glass bottles offer numerous benefits that make them a preferred packaging solution:

-

Durability:Glass is chemically inert and resistant to most substances, preserving product integrity without reacting or leaching chemicals.

-

Recyclability:Glass is 100% recyclable indefinitely without degradation in quality, making it an environmentally responsible choice.

-

Aesthetic Appeal:The clarity and brilliance of glass enhance product presentation, conveying quality and luxury.

-

Non-Toxic:Glass does not contain harmful chemicals like BPA or phthalates, ensuring product safety.

-

Versatility:Glass bottles suit a wide range of products, from beverages and food to cosmetics and pharmaceuticals.

Paupacking’sGlass Bottlesembody these advantages, offering eco-friendly, elegant packaging solutions that meet modern market demands.

Table: Common Glass Bottle Types and Their Features

| Bottle Type | Description | Typical Uses | Key Features |

|---|---|---|---|

| Round | Cylindrical, smooth sides | Beverages, sauces, oils | Versatile, easy to handle |

| Square | Flat sides, sharp edges | Spirits, perfumes | Space-efficient, modern look |

| Oval | Flattened, smooth curves | Cosmetics, luxury goods | Ergonomic, sleek appearance |

| Rectangular | Flat surfaces, angular shape | Pharmaceuticals, personal care | Ideal for labeling, compact |

| Boston Round | Rounded shoulder, cylindrical body | Essential oils, pharmaceuticals | Easy pouring, compatible with droppers |

| Long-Necked | Extended neck for pouring | Wine, beer, spirits | Elegant, reduces spillage |

| Specialty-Shaped | Custom artistic designs | Branding, unique products | Distinctive, customizable |

Applications of Glass Bottles

Paupacking’sGlass Bottlesserve various industries:

-

Food & Beverage:Glass bottles preserve flavor and freshness for juices, wines, oils, and sauces. Their airtight seal and inert nature prevent contamination and spoilage.

-

Cosmetics & Skincare:Glass jars and bottles provide a luxurious feel for serums, creams, perfumes, and lotions. They protect sensitive ingredients from degradation and offer an upscale presentation.

-

Pharmaceuticals:Glass bottles ensure product safety and chemical stability for medicines, supplements, and essential oils. Their compatibility with sterile environments is critical.

-

Aromatherapy:Essential oil bottles made from amber or frosted glass protect contents from UV light, preserving therapeutic properties.

Paupacking designs glass bottles with these applications in mind, merging style with safety and sustainability.

Caring for Glass Bottles

Proper care is essential to maintain the appearance and functionality of glass bottles:

-

Clean bottles regularly with warm water and mild detergent to remove residues.

-

Avoid sudden temperature changes that can cause thermal shock and cracking.

-

Store bottles securely to prevent accidental breakage.

-

Use appropriate closures to maintain product freshness and prevent contamination.

Paupacking provides customers with detailed care instructions to maximize the lifespan and performance of their glass bottles.

Why Choose Paupacking?

Paupacking is a trusted supplier of premiumGlass Bottles, offering:

-

High-Quality Materials:Only the finest glass is used to ensure clarity and durability.

-

Extensive Selection:Wide variety of bottle shapes and sizes to suit every need.

-

Customization:Tailored solutions for branding and unique product requirements.

-

Sustainability:Commitment to eco-friendly practices and recyclable packaging.

-

Global Reach:Reliable shipping and customer support worldwide.

Partnering with Paupacking means choosing excellence in glass bottle manufacturing and design.

This detailed exploration of glass bottle materials, manufacturing, and types equips you with the knowledge to select the perfect bottle for your products. Discover Paupacking’s full range ofGlass Bottlesand elevate your packaging with solutions that combine beauty, durability, and sustainability.