Confused by all the claims about child-resistant packaging but unsure who you can actually trust?

To audit a child-resistant packaging supplier in 2024, you need to verify certifications, test protocols, quality systems, and environmental standards. This checklist helps you confidently evaluate any supplier.

Choosing the right partner isn’t just about price or looks. Safety compliance, testing transparency, and ethical manufacturing are what make a true packaging partner stand out. Let’s walk through the key criteria together.

What Are the Key Compliance Standards for Child-resistant Packaging?

Not all “child-resistant” packaging actually meets legal or safety standards—here’s how to separate the compliant from the careless.

In 2024, suppliers must meet standards such as 16 CFR 1700 (U.S.), ISO 8317 (EU), and ASTM D3475, backed by third-party lab reports and batch traceability.

Why Certifications Matter

Child-resistant (CR) packaging is required by law in many industries, especially for pharmaceuticals, cannabis, and cosmetics. But the term is often misused. Here are the real certifications that matter:

| Region | Standard | Description |

|---|---|---|

| USA | 16 CFR §1700.20 | Regulated by CPSC, requires test with children |

| EU | ISO 8317 | International standard for reclosable CR packaging |

| Global | ASTM D3475 | Classification of CR packaging types |

What Documents You Should Request

-

Third-party lab test reports (not just internal claims)

-

Batch traceability records

-

Quality Control logs and inspection records

-

Sample packaging for personal test

At PauPack, we don’t just meet the minimum—we go further. Our child-resistant packaging lines are tested according to ISO and CPSC protocols, and we maintain full documentation for audits.

How to Verify a Supplier’s Certification and Testing Protocols?

Too many suppliers say they’re “certified” but offer no proof. Let’s change that.

Ask for recent lab reports, video footage of testing, and actual certification numbers you can verify with the issuing body.

Red Flags and What to Watch For

-

Vague answerswhen asked for documentation

-

“In process” certificationswithout ETA

-

Test reports older than 2 years

-

Reports not issued by recognized labs (like SGS, Intertek, TUV)

Actionable Steps for Audit

-

Request lab reports linked to specific SKUs

-

Cross-check certificate numbers with lab databases

-

Ask for a live testing demo or video verification

-

Verify test conditions (number of children, test cycles, failure rate)

PauPack clients receive a compliance pack with every shipment, including lab reports, testing protocols, and a digital library for batch verification. That’s what a responsible supplier does.

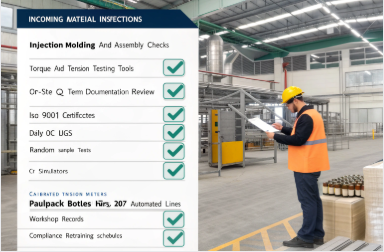

What Factory Auditing Practices Ensure Packaging Safety and Quality?

It’s not enough for a product to pass one test—it has to pass every time, across every batch.

Factory audits should cover quality systems (ISO 9001), raw material control, staff training, and routine stress testing of packaging mechanisms.

What a Real Factory Audit Looks Like

A reliable audit should examine:

-

Incoming material inspection procedures

-

Injection molding and assembly line checks

-

Torque and tension testing equipment

-

On-site QA teams and documentation flow

Checklist for On-Site Visits or Virtual Audits

| Audit Item | What to Ask / Look For |

|---|---|

| QC protocols | ISO 9001 certification, daily QC logs |

| Line inspections | Random sample tests per shift |

| Test environment | Child-resistance simulators, torque meters |

| Staff training records | Regular compliance workshops, training logs |

PauPack operates over 20 automated lines with digital traceability, and our quality system integrates AI-powered defect tracking—something few traditional factories offer.

To audit a child-resistant packaging supplier in 2024, you will need to verify their certifications, testing protocols, quality systems, and environmental standards.

How Do You Assess Material Safety and Environmental Impact?

Today’s brands want safety and sustainability together. It’s no longer either/or.

Ensure your supplier uses food-grade, BPA-free materials and offers eco-friendly alternatives like PLA or recycled PET, all with proper MSDS and REACH certifications.

What to Look For in Materials

-

MSDS Sheets: Confirm material composition and safety

-

RoHS/REACH Compliance: Especially for EU-bound goods

-

PLA / Bio-based Polymers: For sustainable CR packaging

-

Heavy Metal Testing: Especially important for colored plastics

Eco-conscious Evaluation

| Material Type | Eco Indicator | Why It Matters |

|---|---|---|

| PLA | Biodegradable | Reduces plastic waste footprint |

| Recycled PET | Post-consumer content | Supports circular economy |

| Glass | 100% recyclable | Best for repeat-use and upscale branding |

At PauPack, our child-resistant lines include options in biodegradable PLA and recyclable glass, backed by REACH and FDA documentation. We also run 100% renewable energy in manufacturing and 80% closed-loop water systems.

What Red Flags Should You Watch Out for When Vetting Suppliers?

The wrong supplier can cause delays, legal risk, and even recalls. Spot these red flags early.

Avoid suppliers that lack transparency, can’t provide samples or audits, or change pricing/specs mid-process.

Common Supplier Red Flags

-

Inconsistent specifications: Cap doesn’t match container, or dimensions vary

-

Lack of SOPs: “We’ll handle it” is not a system

-

Refusal to provide samples or documentation

-

Too-good-to-be-true pricing

-

Frequent turnover in communication team

Smart Supplier Evaluation Tips

-

Send a sample under NDA and test personally

-

Interview their technical team—not just sales

-

Run a small batch order and inspect delivery

-

Ask for references in your industry

PauPack supports low-MOQ trial orders, full documentation, and dedicated account managers fluent in compliance standards across US, EU, and Australia. We believe in long-term partnerships, not transactional risk.

Why Is Child-resistant Packaging More Critical in 2024 Than Ever?

With the rise in home medication, cannabis products, and DIY cosmetics, unsafe packaging has real consequences.

In 2024, stricter regulations and increased public awareness make child-resistant packaging a legal and ethical necessity across health, wellness, and beauty sectors.

The Expanding Scope of CR Packaging

Traditionally limited to pharmaceuticals, child-resistant packaging is now expected for:

-

Cannabis and CBD products

-

Essential oils and aromatherapy kits

-

Skincare actives (e.g. retinoids, acids)

-

Supplements and herbal concentrates

This shift means more brands—especially indie and DTC lines—must comply with CR standards or risk product bans or lawsuits.

Case Example: From Optional to Mandatory

At PauPack, we helped a US-based wellness brand relaunch their facial oil line after state regulators flagged their previous packaging. With certified dropper caps and ISO-tested safety mechanisms, they’re now compliant in all 50 states—and selling better than ever.

What Should Be Included in a Supplier’s Compliance Portfolio?

Even seasoned buyers can get tripped up by incomplete or outdated documents.

A credible supplier’s portfolio should include lab reports, compliance certificates, material declarations, and batch-level quality records.

Essential Compliance Documents

| Document Type | Why It Matters |

|---|---|

| ISO 8317 / 16 CFR 1700 Certs | Shows packaging meets international CR standards |

| Lab Test Reports (Recent) | Proves real-world safety performance |

| Material Declaration (MSDS) | Ensures safety of all components |

| QA Logs + Batch Records | Allows traceability in case of recalls |

Request digital access and organize these in your internal compliance library. Your QA team will thank you.

PauPack provides every client with a digital compliance vault—updated quarterly—covering every bottle, cap, and closure we manufacture.

How to Evaluate Child-resistant Features in Sample Testing?

Don’t just take their word for it—test it yourself.

Always request physical samples and verify resistance, usability, and consistency through your own internal or third-party testing.

How to Run a Simple In-house CR Test

-

Attempt to open without instructions (simulate child behavior)

-

Ask an adult tester to open and reseal it easily

-

Repeat 10–15 times to check for fatigue or seal failure

-

Drop-test it to see if mechanism breaks or loosens

Key CR Features to Inspect

-

Push-turn, squeeze-slide, or snap-lock functionality

-

Audible “click” or tactile feedback

-

Clear open/close instructions (visual or embossed)

-

No sharp edges or brittle points after multiple uses

We regularly send pre-batch and post-batch samples to clients, with video walkthroughs showing stress tests, torque tolerance, and real-user handling. We don’t just deliver safety—we show the proof.

What Role Does Supply Chain Transparency Play in Audits?

A good supplier knows every link in their chain. A great one lets you see it.

Transparent supply chains allow you to trace materials, check ethical practices, and confirm that safety standards are consistent from raw resin to final shipment.

What to Ask in a Transparency Audit

-

Origin and grade of raw materials

-

Subcontractors involved (mold shops, printers)

-

Worker safety and training programs

-

Use of digital traceability systems (like QR or RFID)

Green Flags

| Practice | What It Signals |

|---|---|

| Real-time batch tracking | Strong inventory and recall control |

| Internal audit teams | Ongoing quality enforcement |

| Open video factory tours | Confidence in their operations |

| COAs from upstream vendors | Validity of raw material quality claims |

At PauPack, we operate with full digital traceability across our 20+ production lines and over 3,000 SKUs. Our blockchain-powered transparency ledger is available for key B2B clients to access in real-time.

How Can You Integrate Sustainability Into Your CR Packaging Strategy?

Child-resistant doesn’t have to mean environmentally resistant.

Choose suppliers that offer eco-friendly CR packaging, such as biodegradable PLA, recyclable PET, or FSC-certified paper components.

Sustainable Meets Safe

The rise of sustainability mandates (especially in the EU and Australia) means brands now need dual compliance:

-

Child safety regulations

-

Environmental performance metrics

Eco CR Packaging Options

| Material | Feature |

|---|---|

| Biodegradable PLA | Compostable in industrial settings |

| Recycled PET (rPET) | Reusable, clear, and high-barrier |

| Bamboo Accents | Fast-regrowth, low-impact decorative elements |

| Glass | Recyclable and perceived as premium |

PauPack’s CR collection includes bamboo-top glass jars, paper-based blister packs, and PLA tubes—all ISO-certified for child resistance. Because protecting kids and the planet shouldn’t be a trade-off.

Conclusion

Auditing child-resistant packaging suppliers in 2024 requires a balanced lens of safety, transparency, and sustainability. Ask tough questions, demand documentation, and never settle for “probably compliant.”