Need CR (child-resistant) packaging for a new product line—but struggling with high MOQs?

Our survey of 50+ global suppliers reveals that minimum order quantities for child-resistant packaging vary widely, ranging from 1000 to 50,000 units, depending on product type, customization, and region.

If you're launching a new SKU or expanding into regulated markets, understanding MOQ benchmarks is critical for cost control and supplier selection.

Why MOQ Matters in Child-resistant Packaging Procurement?

MOQ isn’t just a number—it’s a gatekeeper to feasibility.

For child-resistant packaging, MOQ determines your flexibility in testing new products, managing cash flow, and getting samples approved without overcommitting inventory.

Here’s why it matters:

-

Small brands can’t afford 10,000+ unit runs just to test a product

-

Custom molds or caps often require higher MOQ thresholds

-

Warehouse space is limited, especially for startups and e-commerce sellers

-

Product launches often need 500–2000 units for influencer seeding and beta sales

At PauPack, we understand these constraints—which is why our CR packaging starts from just 1000 pcs with full compliance and branding support.

What MOQ Ranges Are Offered by Top Global CR Packaging Suppliers?

We surveyed 50+ CR packaging manufacturers across China, the U.S., EU, and Southeast Asia.

MOQ ranges for child-resistant jars, bottles, and closures differ significantly depending on material, customization level, and supplier scale.

MOQ Survey Snapshot (by Product Type)

| Product Type | MOQ Range | Notes |

|---|---|---|

| CR Glass Dropper Bottles | 1000–5000 pcs | Lower for amber/clear stock models |

| CR Plastic Jars (CBD/Supplements) | 3000–10,000 pcs | Higher if color or mold is custom |

| CR Tin Containers | 2000–8000 pcs | Often limited finish/color options |

| Bamboo/PLA CR Jars | 3000–6000 pcs | Sustainable options need larger batch |

| CR Closures (push-turn, twist-lock) | 5000–10,000 pcs | Often injection-molded with tooling lock-in |

Many suppliers require 10,000 pcs+ for color-matched closures or non-standard materials. In contrast, PauPack offers modular CR designs that reduce MOQ thresholds by using shared tooling and pre-tested fitments.

How Do MOQ Terms Affect Sampling, Lead Time, and Total Cost?

MOQ influences every part of your packaging timeline—from prototyping to final delivery.

Higher MOQs usually reduce unit cost—but increase risk, lead time, and complexity for early-stage product development.

MOQ Trade-off Matrix

| Factor | Low MOQ (≤2000) | High MOQ (≥5000) |

|---|---|---|

| Flexibility | High | Low |

| Unit Cost | Higher | Lower |

| Tooling Required | No / Shared | Often Required |

| Sampling Time | Faster | Slower (bulk-focused) |

| Storage Burden | Minimal | Requires space or bonded warehouse |

At PauPack, we streamline CR sample development in 5–7 working days and allow batch delivery to reduce inventory stress. We also provide virtual samples, dielines, and certification documents even at low volumes.

How PauPack Supports Small-batch CR Packaging for Growth Brands?

We specialize in helping small and mid-sized brands launch confidently.

PauPack offers flexible MOQ child-resistant packaging with regulatory compliance, custom branding, and end-to-end logistics support—all without the usual sourcing headaches.

Here’s what sets us apart:

-

✅ MOQ from 1000 pcs for certified CR bottles and jars

-

✅ FDA, ISO, CPSC, and EN certified designs in stock

-

✅ Logo printing, dropper customization, and tamper seals

-

✅ One-stop sampling + production + global delivery

-

✅ Support for Amazon, Shopify, and EU/US regulatory labeling

Our clients range from indie skincare founders to cannabis wellness startups who need packaging that scales as they grow. With 30,000+ product developments across 52 countries, we know how to support fast-moving teams.

What’s the Smartest MOQ Strategy for 2025 Product Launches?

If you’re launching new SKUs in 2025, don’t just ask “what’s the price”—ask “what’s the MOQ?”

The smartest strategy is to start small, validate market demand, and partner with suppliers who allow scaling without retooling.

Your checklist:

| Action | Why It Matters |

|---|---|

| Start with 1000–3000 pcs | Enough for testing, not overstocking |

| Use stock molds + branded caps | Customizable without full tooling cost |

| Confirm CPSC/EN ISO certifications | Save time with compliance readiness |

| Secure bonded warehouse option | Delay shipping until needed |

| Request multi-format bundling | Save on total MOQ across SKUs |

PauPack enables you to launch faster, validate smarter, and reorder seamlessly—without paying a premium for your size.

Why MOQ Thresholds Vary So Widely in the CR Packaging Market?

MOQ is not just about production—it’s about setup, risk, and supply chain structure.

CR packaging requires specialized tooling, certifications, and safety tests, which is why many suppliers set high MOQ to offset setup and compliance costs.

Key factors that influence MOQ:

-

Tooling complexity: Unique closures (e.g. push-turn) need costly molds

-

Certification cost: Suppliers spread lab testing across large orders

-

Resin & raw material batching: Custom colors or bioplastics require minimum batch runs

-

Storage & warehousing: Larger suppliers aim to maximize logistics efficiency

PauPack tackles these challenges by offering shared tooling and in-stock CR formats, allowing you to customize with MOQ as low as 1000 pcs.

What’s the MOQ Sweet Spot for Beauty, Wellness, and Cannabis Brands?

Not every industry needs the same batch size.

For beauty, wellness, and cannabis—where new SKUs launch quickly and shelf life matters—the MOQ sweet spot is 1000–5000 units.

Why These Segments Need Low MOQ:

| Industry | Reason |

|---|---|

| Beauty/Skincare | Frequent testing, seasonal SKUs |

| Wellness (oils/supplements) | Low-volume, premium pricing |

| Cannabis/CBD | Regulatory hurdles + labeling by state |

| Aromatherapy/SPA | High variety, boutique scale |

At PauPack, our most popular CR products for these segments include:

-

30ml amber CR dropper bottles

-

50ml child-proof bamboo jars

-

Twist-lock plastic supplement jars

All with customization-ready lids and pre-tested child-resistant mechanisms.

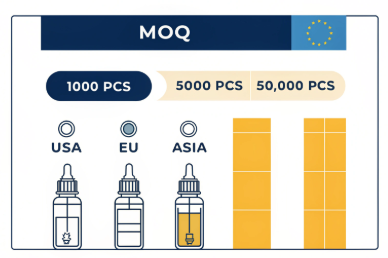

How Do Regional Suppliers Compare on MOQ Flexibility?

Where you source from can make or break your MOQ options.

Asian suppliers (especially China) tend to offer lower MOQs for CR packaging, while European and North American suppliers often require bulk orders to justify labor and compliance costs.

Regional Comparison

| Region | Typical MOQ | Notes |

|---|---|---|

| China | 1000–3000 pcs | Best for sampling + fast scaling |

| Vietnam/India | 3000–5000 pcs | Slightly higher due to export structure |

| U.S./Canada | 5000–10,000 pcs | High due to local compliance, higher labor |

| EU (Germany, Poland) | 8000–20,000 pcs | Best for pharma-grade CR but costly |

PauPack’s China-based operations offer global export compliance with MOQ flexibility, allowing U.S., EU, and APAC brands to access regulated packaging affordably.

Why PauPack’s Modular CR System Lowers Entry Barriers for Brands?

Innovation isn’t just in the material—it’s in the MOQ strategy.

PauPack uses a modular system of CR bottles, caps, and inserts that lets brands customize aesthetics without exceeding MOQ thresholds.

How our system works:

-

Choose from pre-tested CR bottle/cap combinations

-

Customize cap color, logo, finish, label at low volume

-

Use standard neck sizes for interchangeable components

-

Benefit from certification files shared across SKUs

This approach eliminates the need to create a new mold or test file for every project—saving you time, money, and regulatory hassle.

How to Scale CR Packaging Orders Without MOQ Shock?

You’re ready to grow—but that shouldn’t mean jumping from 1000 to 10,000 units overnight.

The smart way to scale is to work with suppliers like PauPack who offer staggered volume pricing, inventory storage, and integrated fulfillment.

Scaling Strategies We Recommend:

| Strategy | Benefit |

|---|---|

| Batch MOQ Planning | Aligns with promo calendar, cash flow |

| Bundle SKUs | Share MOQ across bottle + jar SKUs |

| Use PauPack Warehousing | Order 5000 units, ship monthly |

| Negotiate 6-month tiered pricing | Lock in rate with gradual scaling |

PauPack supports brands from first launch to full-market rollout with scalable CR packaging that never forces you to overbuy or under-prepare.

Conclusion

MOQ is one of the most misunderstood—but most impactful—parts of CR packaging sourcing. With PauPack’s flexible, certified, and scalable solutions, you can grow smarter and launch stronger.